CNC Wood Routing Support

- Home

- CNC Programming Services

- CNC Wood Routing Support

Smart CNC Routing Support for Bespoke Woodworking and Modular Builds

Precision matters in woodworking, especially when mass-producing modular furniture or fabricating custom joinery. Our CNC Wood Routing Support service is tailored for millwork studios, furniture manufacturers, and interior fabricators who rely on clean cuts, efficient layouts, and joinery accuracy. From cut-ready files to production-friendly layouts, we deliver solutions that reduce errors and keep your workflow moving smoothly.

Tools We Use

What We Offer

Clean CAD-to-CNC File Conversion

We transform your designs into router-ready DXF or DWG files, organized and optimized for compatibility with your CAM tools and machine specs.

Joinery Detailing Built for Fabrication

Whether it's dowels, dados, mortise and tenon, or pockets for knock-down fittings, we program them in with clarity and accuracy.

Panel Optimization and Nesting

Each layout considers sheet size, edge alignment, grain direction, and hardware zones, resulting in intelligent material use and fewer post-cut adjustments.

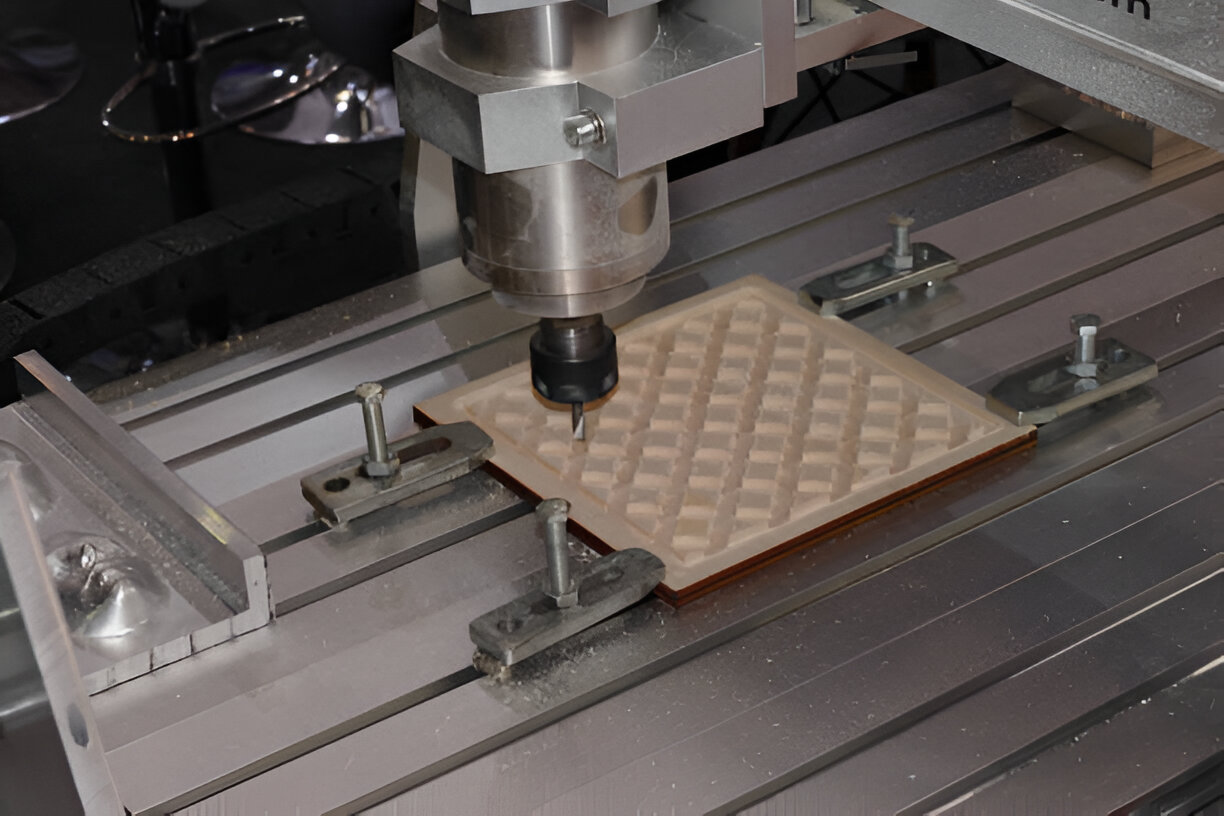

Carving and Contour Programming

We support decorative work like inlays, chamfers, and curved panel edges with clean toolpaths designed for MDF, birch ply, or hardwood.

Routing-Specific Tolerancing

Files are prepared with bit size compensation, clearances for edge banding, and plunge-safe start points to avoid tear-out or burning.

Documentation That Speaks to Your Team

Assembly sketches, part ID tags, and orientation marks; everything your production crew needs to cut, label, and assemble without chasing details.

Our industries

-

Machine Manufacturing

-

Automobile Industry

-

Oil & Gas Industry

-

Heavy Fabrication

-

Sheet Metal Manufacturing

-

Millwork Joinery

-

Furniture Manufacturing

CAD conversion Process

The CAD conversion process at ZetaCADD involves a meticulous approach from physical or outdated designs to accurate and editable digital CAD files.

Consultation

Our technicians consult with clients and try collecting as much information about the project.

Quotation

After the scope of the project is understood, our experts evaluate and offer a price quote.

Feedback & Reviews

To prevent any last-minute changes, Polosoft prefers to get client input at every stage.

Delivery

Final drafts are checked by our professional team of quality analysts.

Get your shop floor routing-ready, without the back-and-forth

We speak the language of designers and machinists so your team can focus on output, not file prep.

Introduce Our Projects

Testimonials

Courtney Henry / Customers in U.S.A

Marry Tonheim / Customers in UK

Anna Richmond / Customers in SA

Read Most

Frequent Questions

Yes. We program joinery like dowels, dadoes, rabbets, and mortise and tenon into the actual cut paths to avoid manual drilling or template setups.

Absolutely. We consider grain direction, face orientation, and edge treatments during nesting and pathing.

Yes. We routinely prepare part libraries and batch layouts for modular systems, including cabinets, shelving, and wall panels.

We accept DXF, DWG, STEP, or your preferred CAD format. If your design is still conceptual, we can work with sketches and build from there.

No, we also support hardwood routing with appropriate toolpath strategies and plunge control to minimize tool wear and chipping.

Yes. We provide labeled parts, exploded views, and orientation visuals to assist cutting, sorting, and assembling all in one clear handover.