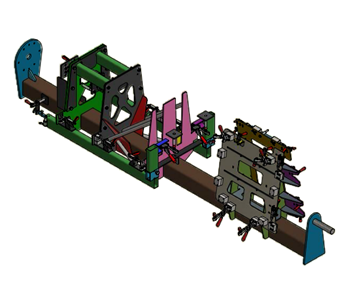

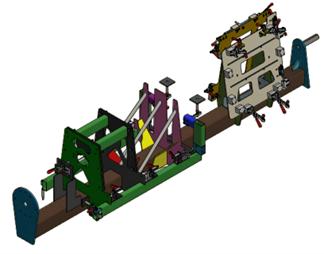

Robotic Welding Jig & Fixture for Baler Manufacturing

- Home

- Business Case Studies

- Robotic Welding Jig & Fixture for Baler Manufacturing

Client

A leading Ireland-based manufacturer in the Balers and Compaction Equipment Manufacturing industry.

Objective

To improve the precision and efficiency of their robotic welding process for assembling the main chassis frame, top and bottom doors, and door closer assemblies of their 40 Baler model by implementing a custom-designed jig and fixture system.

Needs

A jig and fixture system capable of securely holding multiple complex assemblies in precise positions during robotic welding, ensuring dimensional consistency, quick setup, and ease of operation, while accommodating both production and consumable components for their 40 Baler model.

Challenges

Our client, a leading manufacturer of balers and compaction equipment in Ireland, needed a custom-designed jig and fixture system to improve the precision and efficiency of their robotic welding process. Specifically, the system was required for assembling the main chassis frame, top and bottom doors, and door closer assemblies of their 40 Baler model.

The challenge lay in creating a fixture setup that could securely hold multiple complex assemblies in precise positions during robotic welding, ensuring dimensional consistency, quick setup, and ease of operation while accommodating both production and consumable components.

Solution

Zetacadd Engineering Services delivered a comprehensive solution involving:

- Client Requirement Analysis: Engaged with the client’s engineering team to fully understand assembly sequences, weld points, operational space constraints, and safety considerations for robotic operations.

- Reverse Engineering & Fixture Strategy: Studied the existing baler components and workflows to identify fixture points, clamp types, and consumable interfaces. This included analyzing assemblies like:

- Chassis and Doors Jig Weld Assembly

- Head Jig Weld Assembly

- Base Clamp Assembly

- Toggle Clamps (Destaco 210-U, 604-MM)

- Door Closer Positioners and Clamp Assemblies

- 3D Modelling in Autodesk Inventor: Created a detailed 3D Inventor model covering all fixture assemblies, including:

- Hinge block and positioner assemblies

- Door closer bushing and clamp mechanisms

- Removable and consumable jig plates

- Precise clamp positioning as per tolerance standards (as defined in the drawing’s tolerance table)

- Production-Ready Drawings: Developed accurate, annotated manufacturing drawings for over 50+ components and sub-assemblies, adhering to the client’s required tolerances and welding specifications (e.g., tack welds only, tab and slot positioning).

Result

The project delivered:

- Complete 3D assembly models and detailed drawings for manufacturing the robotic welding jigs and fixtures.

- Optimized clamp and positioning layouts for top & bottom door, door closer, and chassis assembly welding.

- Improved welding accuracy, setup repeatability, and operational safety within the robotic cell.

- Reduced fixture setup times and minimized production downtime through precise, user-friendly designs incorporating standard parts like Destaco toggle clamps and indexing plungers.

The client successfully implemented the jigs and fixtures into their robotic welding line, achieving higher product consistency and streamlined production workflows for the 40 Baler model.