CAD Modeling

- Home

- Mechanical Engineering Services

- CAD Modeling

Transform Your Designs with Expert CAD Modeling Services

Enhance your engineering projects with our advanced CAD modeling services. Utilizing the latest 3D CAD tools and techniques, we transform initial concepts into precise, functional 3D models ready for production.

Tools We Use

Detailed and Precise CAD Modeling for Various Industries

Our CAD modeling and SolidWorks-certified experts specialize in creating detailed and accurate 3D models that streamline development and enhance manufacturability. From initial sketches to final design, experience precision at every step.

3D Solid Modeling, Surface Modeling & Sheet Metal Modeling

Create detailed and complex models with our comprehensive 3D modeling capabilities, ensuring accuracy and quality in every design.

3D Parametric Feature-based CAD Modeling

Utilize parametric modeling to maintain consistent and editable design elements, enabling easy updates and revisions.

3D Configured Part/Assembly Modeling

Develop configured models that are ideal for varied applications, enhancing both flexibility and functionality.

3D Modeling from Conceptual Sketch, 2D Drawings, Images & PDF Files

Transform raw concepts and traditional media into fully realized 3D CAD models, facilitating a smooth transition from concept to production.

3D Modeling of Millwork & Bespoke Furniture with Rendering

Custom millwork and furniture models bring architectural details to life, enhanced with realistic rendering for the final visual assessment.

3D Assembly Design with Clearances, Interference Detection & Motion Analysis

Ensure mechanical integrity and optimal functionality with a comprehensive assembly design that includes a detailed analysis of moving parts.

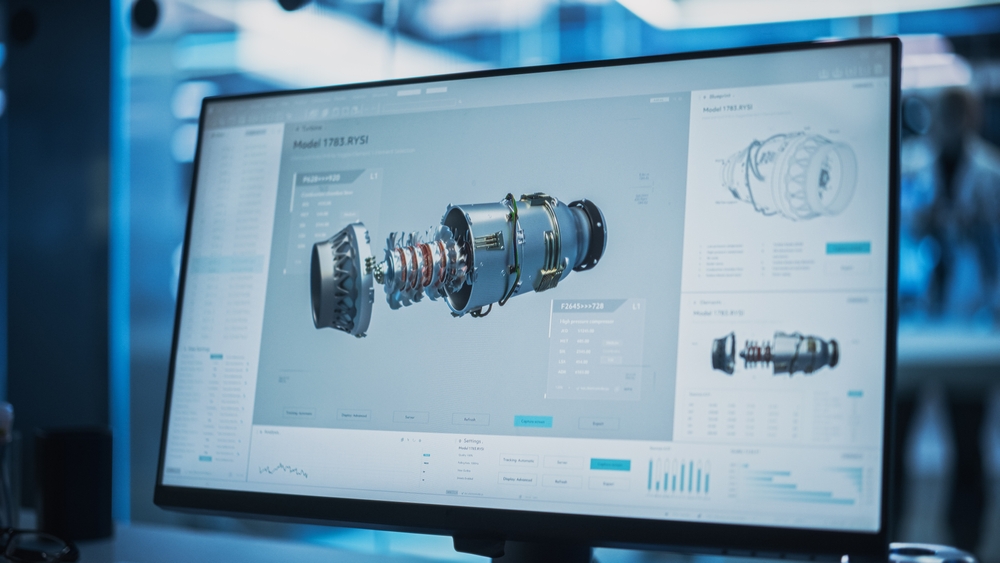

3D Exploded Views of Assemblies & 3D Section Views

Visualize the internal components and assemblies with exploded and sectional views, crucial for documentation and detailed analysis.

3D Modeling with Top Down & Bottom Up Approach

Adapt flexibly between top-down and bottom-up design approaches to suit project requirements and ensure comprehensive development.

Casting and Injection Molding Parts

Prepare models for casting and injection molding with precise specifications to ensure flawless manufacturing execution.

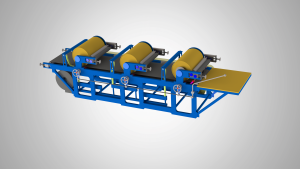

Industrial, Construction, Piping, Fabrication Parts Modeling

Specialize in diverse industries by creating specific models for industrial machinery, construction elements, piping systems, and fabricated parts.

Welded Structures and Frames

Design robust welded structures and frames tailored to support substantial loads and stresses in various operational environments.

Our industries

-

Metal Fabrication

-

Machine Manufacturing

-

Heavy Engineering

-

Automobile Industry

-

Oil & Gas Industry

-

Construction

-

Process Industry

CAD conversion Process

The CAD conversion process at ZetaCADD involves a meticulous approach from physical or outdated designs to accurate and editable digital CAD files.

Consultation

Our technicians consult with clients and try collecting as much information about the project.

Quotation

After the scope of the project is understood, our experts evaluate and offer a price quote.

Feedback & Reviews

To prevent any last-minute changes, Polosoft prefers to get client input at every stage.

Delivery

Final drafts are checked by our professional team of quality analysts.

Avail Best-in-class Services At Affordable Rates

Introduce Our Projects

- CAD Modelling Detailing

Testimonials

Courtney Henry / Customers in U.S.A

Marry Tonheim / Customers in UK

Anna Richmond / Customers in SA

Read Most

Frequent Questions

Our 3D parametric modeling allows for the dynamic adjustment of design parameters, automatically updating related dimensions and features. This capability is crucial for scaling parts or assemblies according to varying specifications without compromising design integrity.

The top down approach allows us to design complex assemblies by starting with a general layout and then detailing individual components, ideal for ensuring system-level compatibility. Conversely, the bottom-up approach assembles designs from individual components to form a whole, allowing for detailed focus on each part before final assembly and enhancing design accuracy and integration.

We utilize advanced CAD software like SolidWorks and Autodesk Inventor, which provide sophisticated tools for interference checking and motion analysis. These tools help identify potential collisions and mechanical conflicts in moving assemblies, ensuring that all mechanical components operate smoothly without failures.

For casting and injection molding, precision is critical to avoid costly manufacturing errors. We employ specialized CAD tools that simulate the mold filling, cooling, and warping processes to predict and correct potential defects in the design phase, ensuring that the models adhere to manufacturing tolerances and material specifications.

Our 3D exploded and section views are crafted using techniques that highlight each component and its placement within an assembly, providing clear visual guidance for assembly or maintenance procedures. These views are particularly beneficial for identifying part relationships and assembly sequences in complex products.

We deliver CAD models in a variety of industry-standard file formats suited to different applications and platforms. For engineering and manufacturing, we provide formats such as STEP for solid models, which is widely compatible across mechanical CAD systems, and IGES for surface models, ensuring interoperability.

For visualization and simulation, we offer formats like STL for 3D printing and OBJ for 3D graphics and animation. Additionally, we support native file formats specific to CAD systems such as SolidWorks (SLDPRT), Autodesk Inventor (IPT), and CATIA (CATPart), ensuring seamless integration with your existing workflows and tools.