Mold Design Services

- Home

- Mechanical Engineering Services

- Mold Design Services

Precision Mold Design Services for Enhanced Product Performance

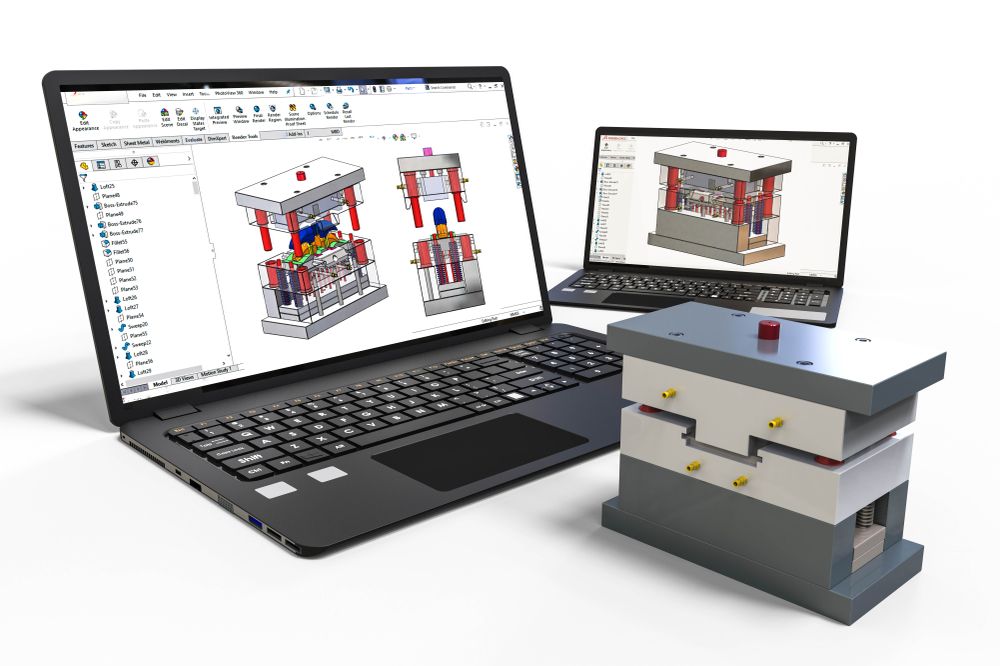

Leverage our expert mold design services to ensure your products are optimized for performance and manufacturability. Utilizing advanced CAD and simulation technologies, we create mold designs that are precise, functional, and ready for production.

Tools We Use

Tailored Mold Design Solutions to Meet Your Manufacturing Needs

Our mold design services are dedicated to providing comprehensive design solutions that prepare your projects for seamless manufacturing, focusing on industries such as plastics, automotive, consumer goods, and medical devices.

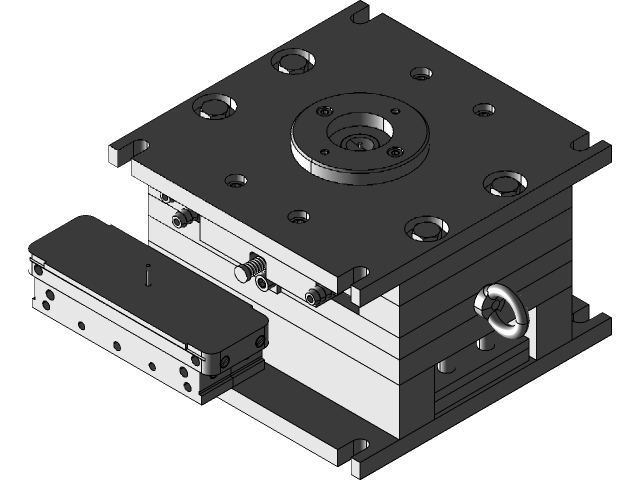

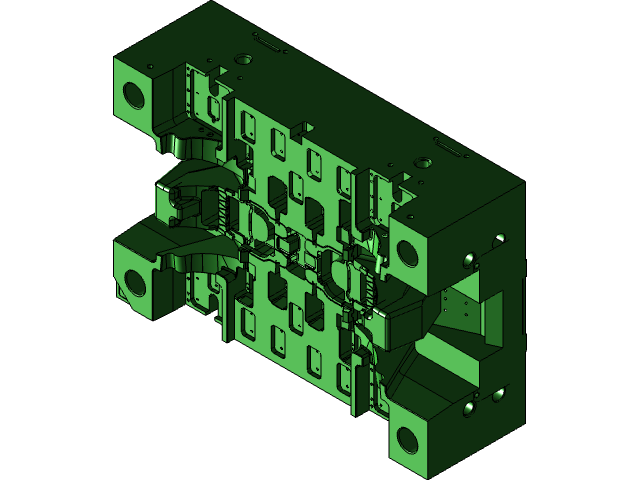

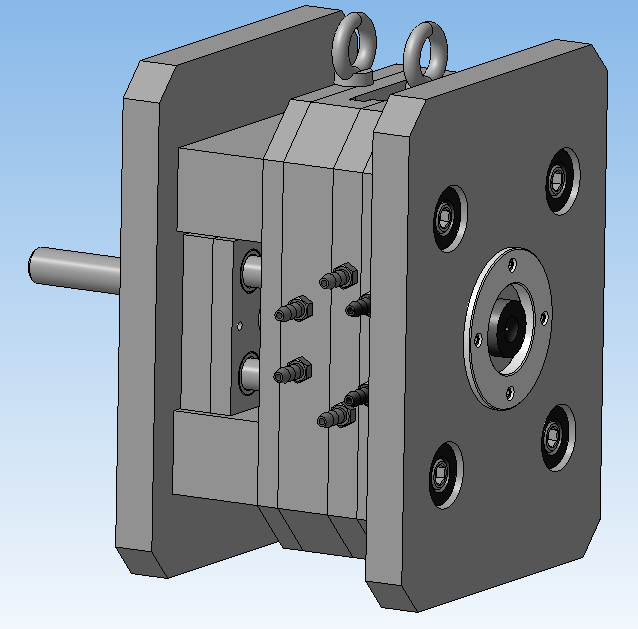

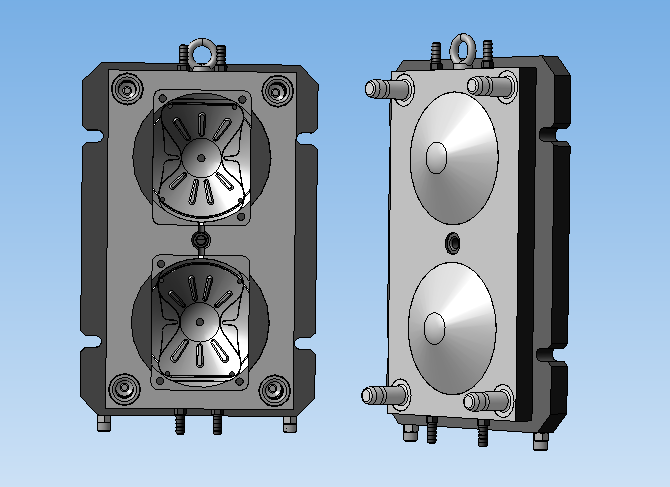

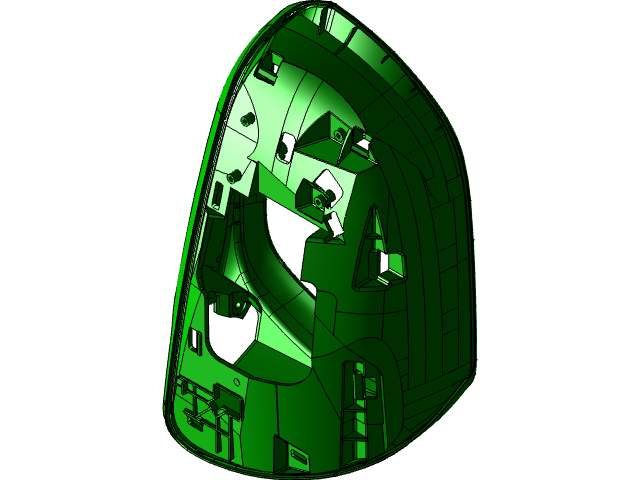

3D CAD Modeling for Molds

Develop detailed mold designs using advanced 3D CAD modeling techniques, ensuring high precision and functionality.

Simulation and Flow Analysis

Utilize simulations to analyze mold flow, material behaviors, and thermal properties, enhancing the mold’s manufacturability and quality.

Tooling Design and Material Selection Guidance

Provide guidance on tooling configurations and material selections that suit specific applications aimed at improving mold performance and longevity.

Design Iterations Based on Prototype Feedback

Incorporate feedback from prototype testing to refine mold designs, ensuring that designs are optimized before handing them over for manufacturing.

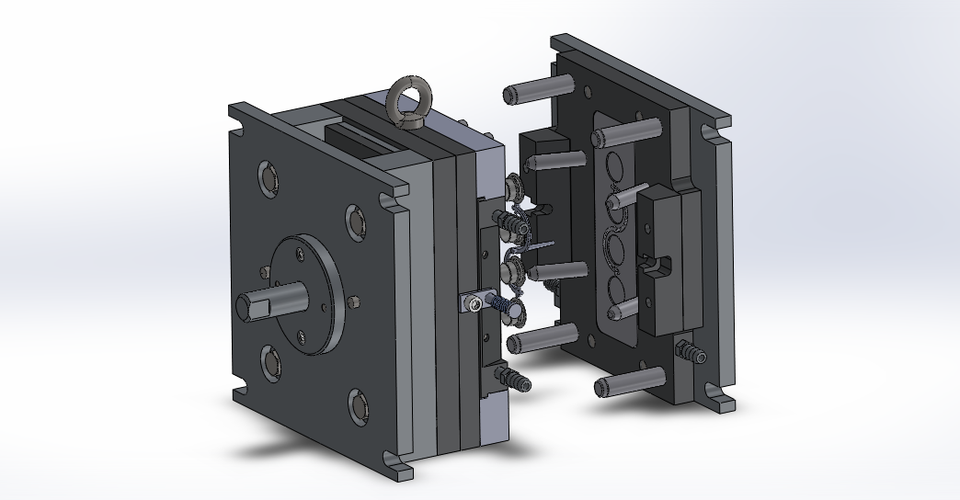

Complex Mold Design Capabilities

Offer designs for complex molds, including multi-cavity, insert, and family molds, designed to meet stringent manufacturing specifications.

Integration with Manufacturing Processes

Design molds that integrate seamlessly with existing manufacturing processes, supporting efficient production workflows.

Cost-Efficiency Analysis

Conduct cost-efficiency analysis to help align mold design choices with budgetary constraints and project goals.

Our industries

-

Metal Fabrication

-

Machine Manufacturing

-

Heavy Engineering

-

Automobile Industry

-

Oil & Gas Industry

-

Construction

-

Process Industry

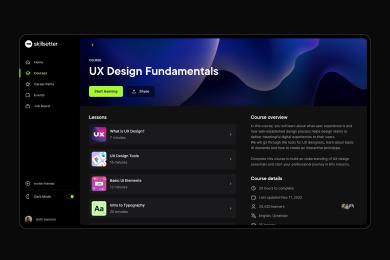

CAD conversion Process

The CAD conversion process at ZetaCADD involves a meticulous approach from physical or outdated designs to accurate and editable digital CAD files.

Consultation

Our technicians consult with clients and try collecting as much information about the project.

Quotation

After the scope of the project is understood, our experts evaluate and offer a price quote.

Feedback & Reviews

To prevent any last-minute changes, Polosoft prefers to get client input at every stage.

Delivery

Final drafts are checked by our professional team of quality analysts.

Consult with Our Mold Design Experts

Introduce Our Projects

Testimonials

Courtney Henry / Customers in U.S.A

Marry Tonheim / Customers in UK

Anna Richmond / Customers in SA

Read Most

Frequent Questions

We specialize in a variety of mold designs, including injection, compression, and transfer molds, tailored to a range of manufacturing applications.

Precision in our designs is ensured through the use of state-of-the-art CAD software and mold simulation tools that accurately predict and optimize mold performance.

Yes, our team is skilled in handling designs that involve complex geometries or require specific materials, ensuring detailed attention to every aspect of mold functionality.

Our mold designs are crafted using industry-leading software such as SolidWorks, Autodesk Moldflow, and Siemens NX to ensure compatibility and precision.

We maintain an iterative design process that includes regular reviews and adjustments based on client feedback to ensure the final design meets all specifications and expectations.

We optimize mold designs for cost-efficiency by evaluating multiple design scenarios, using simulation to predict and minimize potential production issues, and suggesting alternative design elements that reduce costs without compromising quality.