Sheet Metal Design Services

- Home

- Mechanical Engineering Services

- Sheet Metal Design Services

Advanced Sheet Metal Design Services: Precision Engineered for Manufacturing

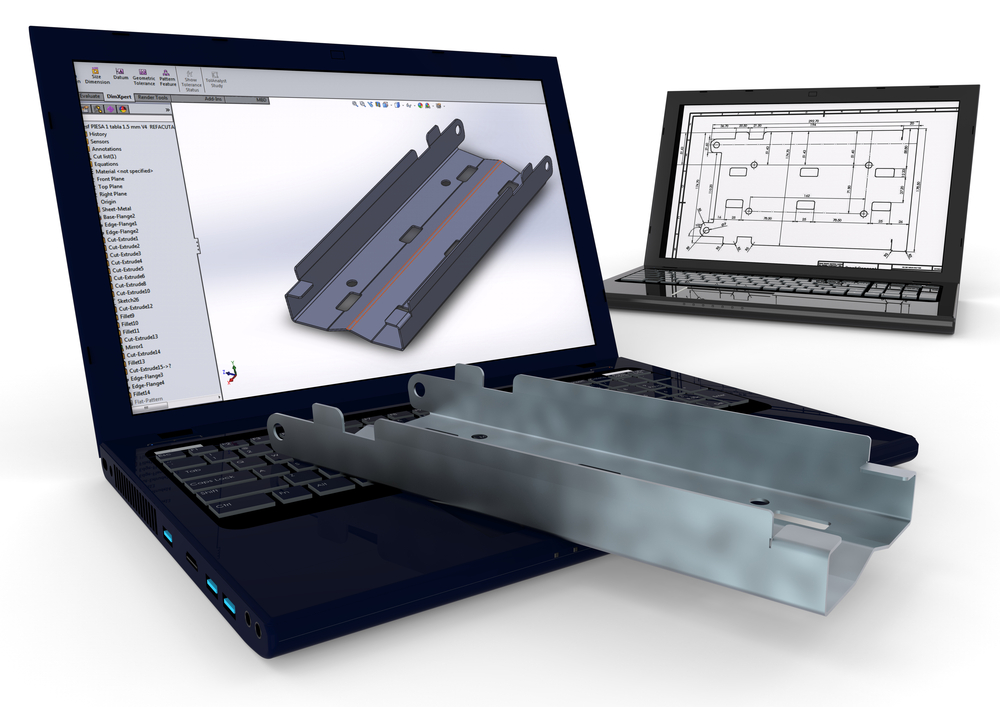

Improve your fabrication processes with our specialized sheet metal design services. Using advanced SolidWorks capabilities and precise engineering practices, we deliver designs optimized for production efficiency and cost-effectiveness.

Tools We Use

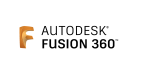

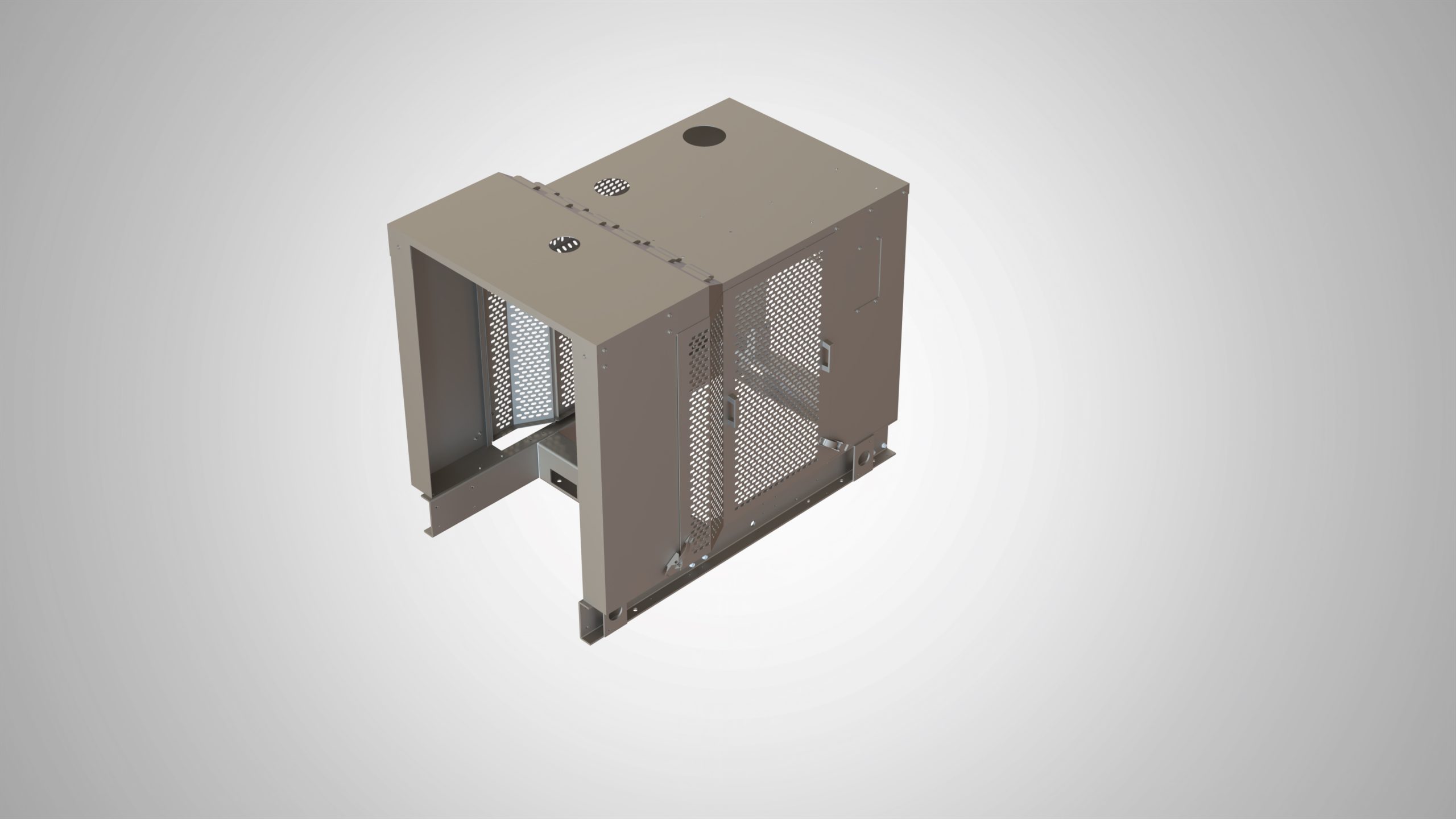

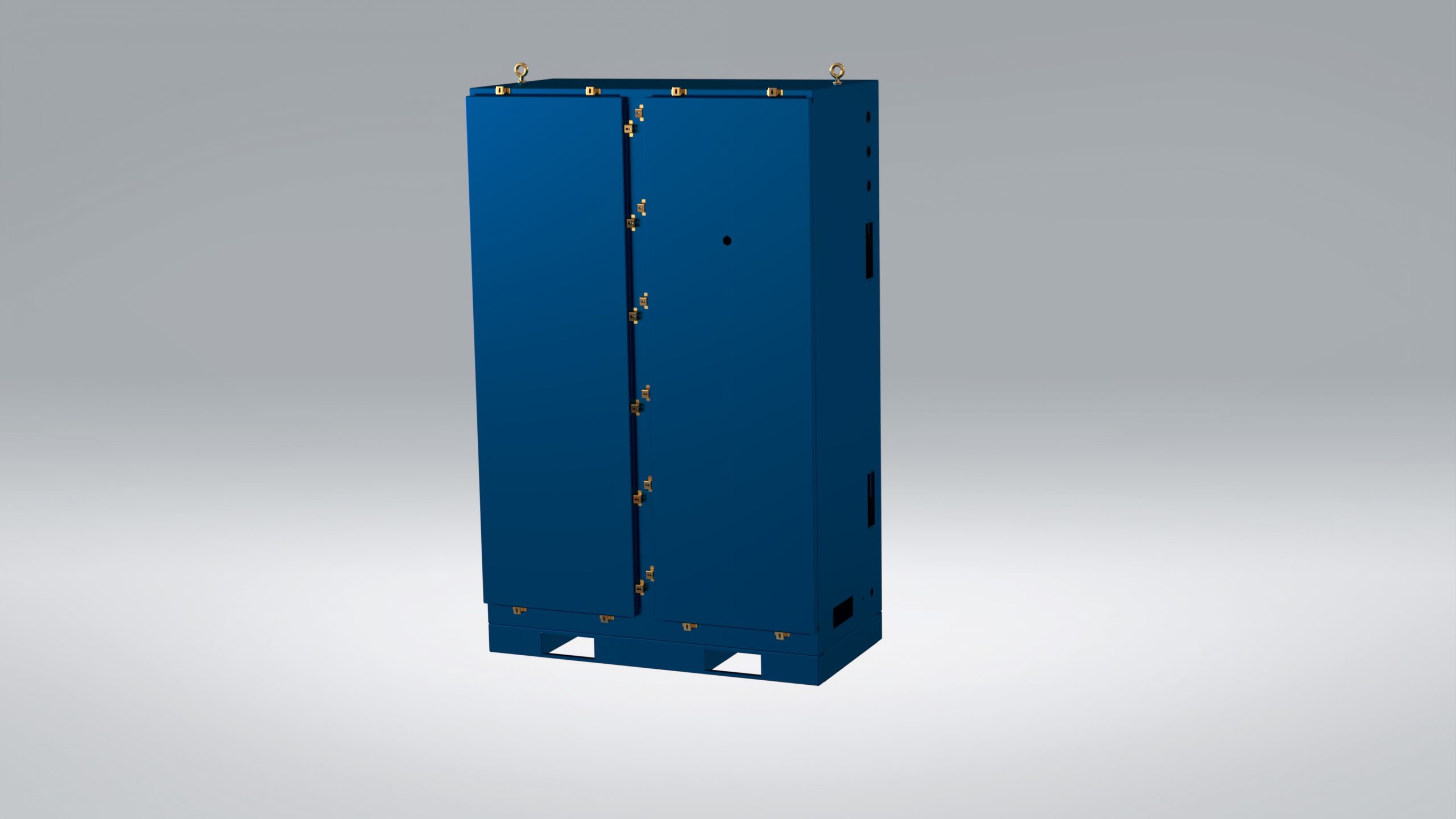

Comprehensive 3D Sheet Metal Design and Fabrication Solutions

From complex assemblies to detailed fabrications, our sheet metal design services cater to diverse industry needs, ensuring precision and adherence to manufacturing standards.

3D Parametric Modeling

Leverage our 3D parametric modeling for sheet metal parts, incorporating design for manufacturability (DFM) and assembly (DFA) to optimize production processes.

Sheet Metal Assemblies

We utilize both bottom-up and top-down approaches to design accurate sheet metal assemblies tailored to your project requirements.

Design Parameters Calculation

Our services include precise calculations for the K-factor, bend deduction, and bend allowance, essential for accurate sheet metal bending.

Conversion to Sheet Metal Parts

Convert solid and surface models into sheet metal parts with specific parameters to meet exact design needs.

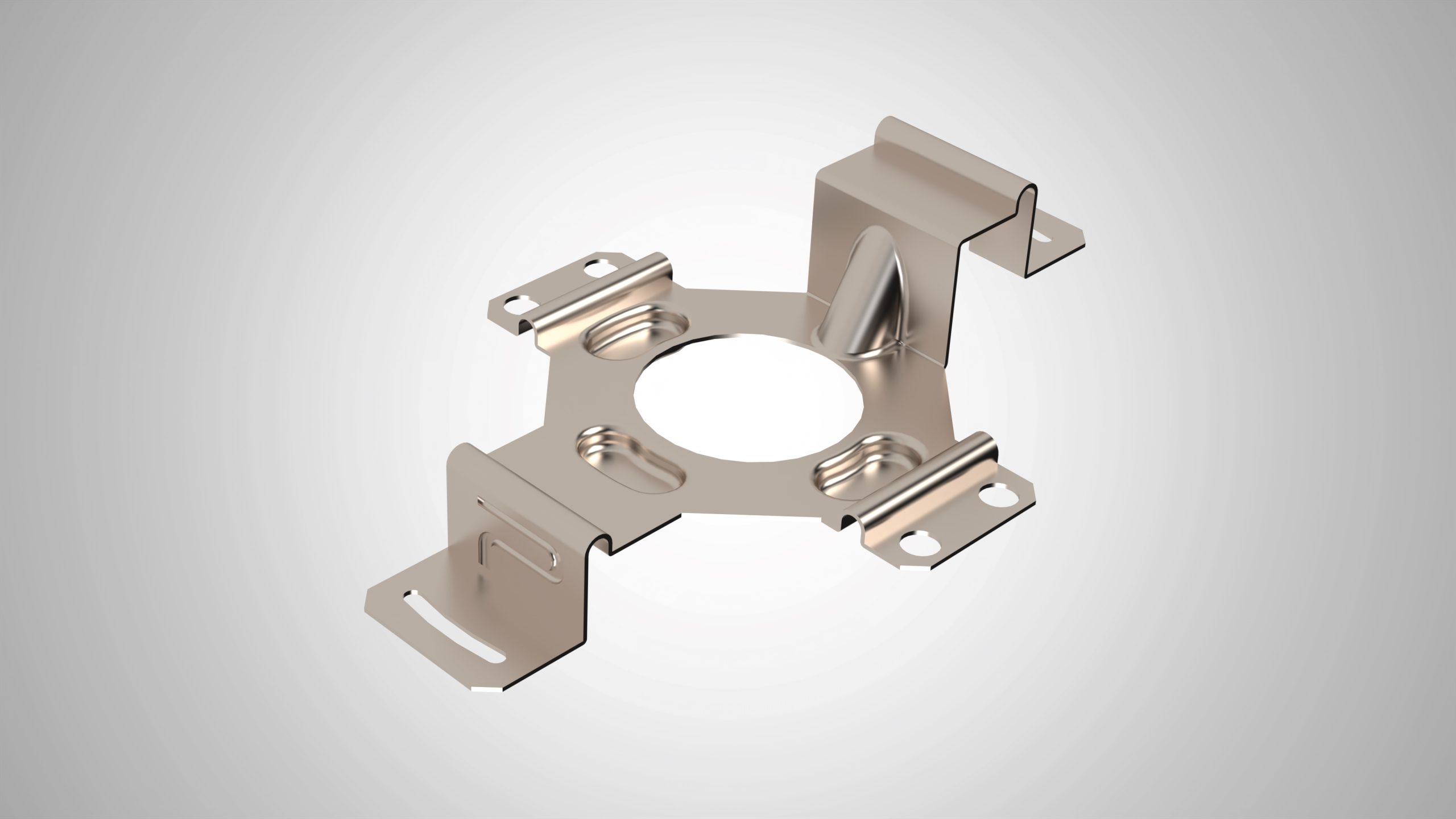

Advanced Feature Design

Design detailed features like ribs, louvers, lances, and embosses using forming tools for enhanced functionality and aesthetics.

Flat Pattern Preparation

Prepare flat pattern views complete with bend lines and notes, ready for CNC press brake operations.

Nesting for Cutting

Optimize material usage with nesting layouts in DXF format, ideal for laser and plasma cutting processes.

Detailed Drawings and Documentation

Receive comprehensive drawings of sheet metal parts and assemblies, including fabrication details, welding symbols, and bills of materials.

Estimation and Costing

Get accurate estimations and costing for your sheet metal design projects, helping you budget effectively and reduce expenses.

Our industries

-

Metal Fabrication

-

Machine Manufacturing

-

Heavy Engineering

-

Automobile Industry

-

Oil & Gas Industry

-

Construction

-

Process Industry

CAD conversion Process

The CAD conversion process at ZetaCADD involves a meticulous approach from physical or outdated designs to accurate and editable digital CAD files.

Consultation

Our technicians consult with clients and try collecting as much information about the project.

Quotation

After the scope of the project is understood, our experts evaluate and offer a price quote.

Feedback & Reviews

To prevent any last-minute changes, Polosoft prefers to get client input at every stage.

Delivery

Final drafts are checked by our professional team of quality analysts.

Get a Quote for Your Sheet Metal Project

Introduce Our Projects

- Sheet Metal Design

Testimonials

Courtney Henry / Customers in U.S.A

Marry Tonheim / Customers in UK

Anna Richmond / Customers in SA

Read Most

Frequent Questions

Our use of advanced SolidWorks technology combined with thorough DFM and DFA processes ensures that every design is optimized for cost-effectiveness and manufacturability.

Precision is achieved through rigorous parameter calculations, detailed modeling practices, and continuous validation against industry standards.

Yes, our expertise in both top-down and bottom-up design approaches allows us to handle complex assemblies with multiple interdependent components.

We deliver sheet metal designs in various formats, including DXF for cutting paths, DWG for general fabrication, and native SolidWorks files for further modifications.

Designs are optimized by creating accurate flat patterns that include all necessary bend lines and notes, ensuring efficient and precise CNC operations.

We provide detailed drawings that include all necessary fabrication details, welding symbols, and assembly instructions to support seamless manufacturing processes.