Competition pushes manufacturers to do more with less. DFM uses manufacturing insights early in the design process and strategically creates smarter, simpler, and more cost-effective products, giving companies the edge they need to survive a competitive market space. What is DFM? DFM (Design for Manufacturing) is an engineering practice that focuses on the practical aspects […]

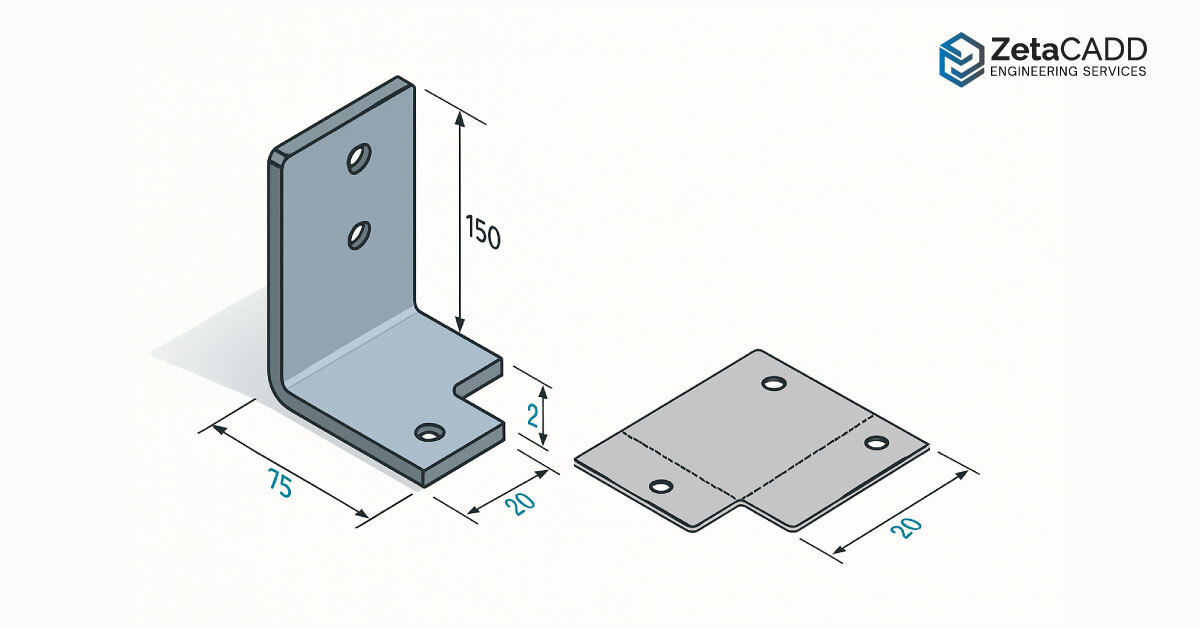

ZetaCADD is a provider of 3D sheet metal modeling services for clients around the globe. From manufacturing and automobiles to the heavy engineering and construction industry, our sheet metal design expertise has helped our clients optimize production and create lightweight, durable, and cost-effective products. How do we do this? It entails prioritizing the need for […]

CAD conversions have revolutionized the way projects are handled. Over the years, CAD conversions have progressed from 2D drafts and 3D models to highly sophisticated file formats that support immersive experiences and real-time collaborations. Technology has fuelled realistic visualizations and brought high precision and accuracy to the table. However, every project is different and has […]

Innovation prevents stagnation. It drives new solutions and helps businesses meet the ever-evolving needs of customers. Result? Businesses get an edge over the competition, and they thrive. Along with innovation, TTM (Time-to-market) is equally critical for innovative product development. The faster an innovation comes to market, the more likely it is to capture market share […]

Construction companies, Architects, Engineers, and Designers often hire CAD conversion services to convert their hand-drawn drafts, blueprints, or scanned images into digital CAD (computer-aided design) files. The high-precision computer-aided designs facilitate better collaboration and communication across teams. It is not unusual for businesses to look for the cheapest services. At the onset, this might seem […]

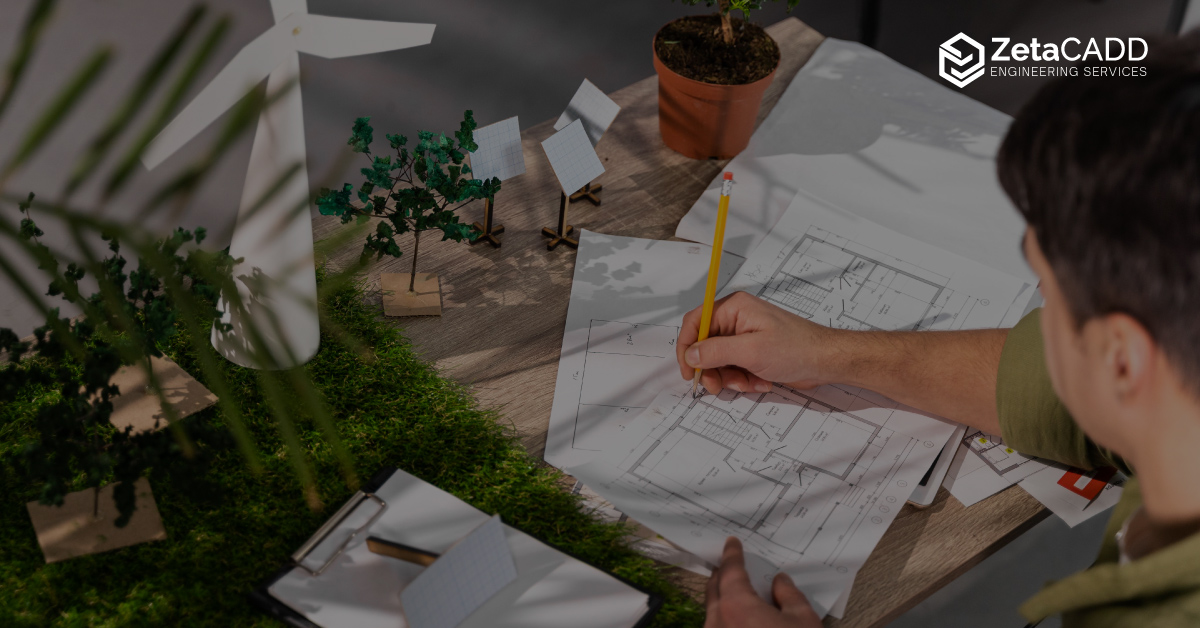

Sustainability is no longer a luxury—it has become a guiding principle for businesses and designers seeking to create enduring, responsible spaces. Nowhere is this more apparent than in contemporary architecture, where eco-friendly practices are woven into every stage of craftsmanship. Millwork—encompassing wood-based fixtures such as paneling, molding, and cabinetry—is a core element in interior design, […]

Design for Manufacturability (DFM) is more than just a smart manufacturing strategy—it’s a vital step towards more sustainable and efficient production. By integrating DFM, companies can cut production costs by up to 50% while improving product quality and market readiness. DFM acts as a link between manufacturing and design, and by passing knowledge on limitations […]