Applying Design for Manufacturability (DFM) Techniques in New Product Development

Design for Manufacturability (DFM) is more than just a smart manufacturing strategy—it’s a vital step towards more sustainable and efficient production. By integrating DFM, companies can cut production costs by up to 50% while improving product quality and market readiness.

DFM acts as a link between manufacturing and design, and by passing knowledge on limitations such as machine capabilities, material characteristics, and manufacturing procedures, it bridges the gap.

But there’s a bigger picture: DFM also dramatically reduces environmental impacts. It helps save resources, cut emissions, and supports our global sustainable need

This article explores how DFM can make manufacturing leaner and greener, focusing on key techniques and sustainable practices.

How to Implement DFM in Product Design?

Implementing Design for Manufacturability (DFM) in product design is a strategic approach that integrates manufacturing considerations early in the design process to improve the final product’s cost-effectiveness, efficiency, and quality.

Here’s a structured way to implement DFM in product design:

- Early Collaboration: Engage both design engineers and manufacturing teams from the start.

- Standardization: Utilize standardized components and materials to reduce complexity and cost.

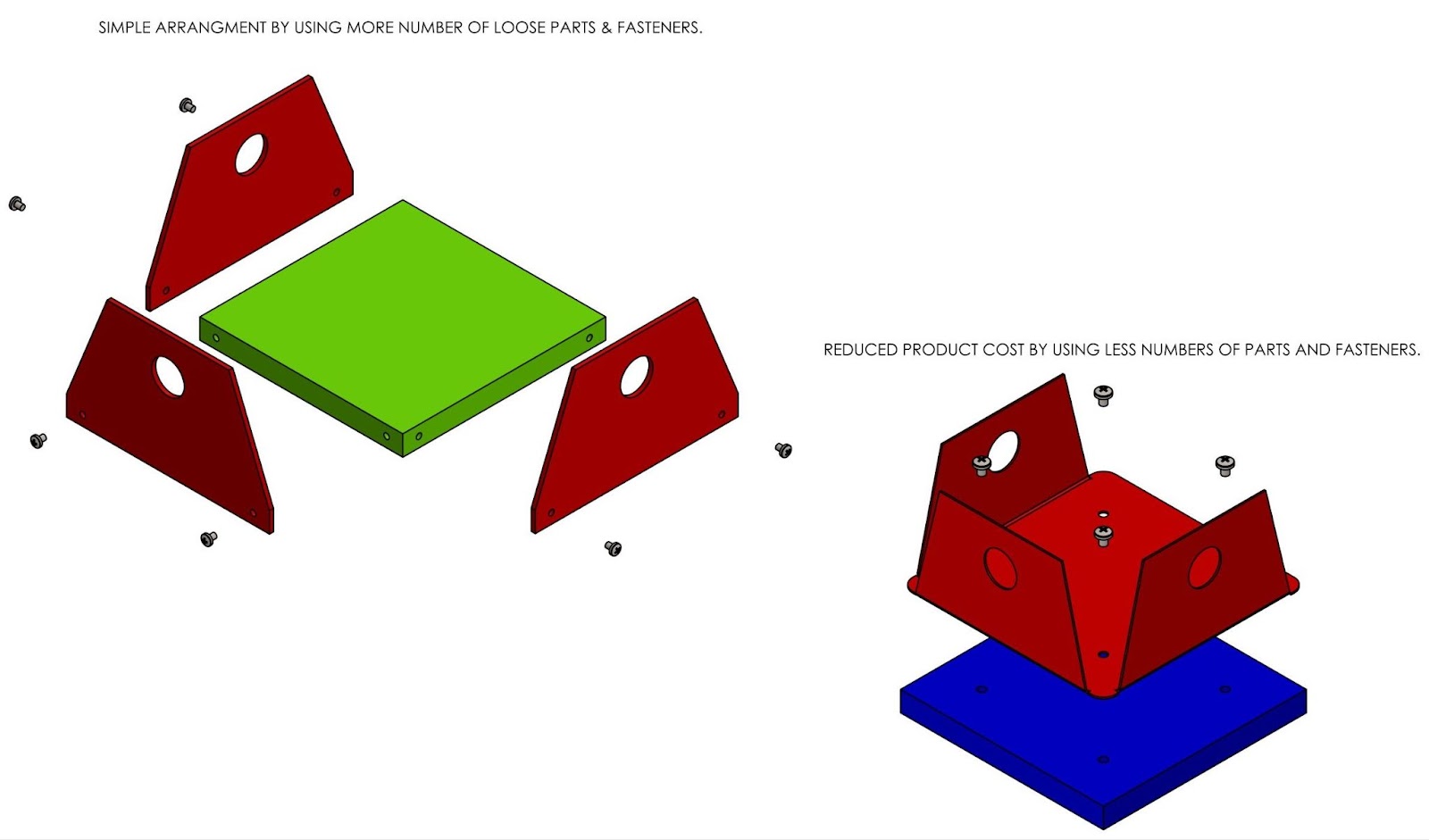

- Simplification: Minimize the number of parts and assemblies to decrease production and assembly time.

- Manufacturing Techniques Analysis: Choose manufacturing processes that align with the product’s design and volume.

- Material Selection: Choose materials that are appropriate for the product’s use and manufacturing processes while being cost-effective.

- Prototyping and Testing: Rapid prototyping tests design manufacturability and identify design flaws early.

- Tolerance Analysis: Set realistic tolerance levels for manufacturing capabilities and product needs.

- Feedback Loops: Implement continuous feedback mechanisms from all stakeholders to improve the design.

- Documentation and DFM Guidelines: Keep detailed design and manufacturing documentation and establish specific DFM guidelines.

- Continuous Improvement: Regularly review and refine products and processes based on previous experiences.

Sustainable Product Design in DFM

Sustainable product design reduces environmental impacts during manufacturing while maintaining cost-efficiency, productivity, quality, and performance. By incorporating DFM principles, manufacturers can optimize the use of resources and energy, enhancing overall functionality.

Strategies for Sustainable DFM:

- Local Sourcing of Materials: By sourcing materials locally, you can minimize transportation costs and emissions. This approach supports local businesses and reduces the carbon footprint associated with long-distance transportation.

- Energy-Efficient Manufacturing Techniques: Select manufacturing processes that require lower energy consumption, such as cold forming or powder coating. These techniques are better for the environment and can reduce operational costs.

- Modular Component Design: Design components to be easily disassembled and repaired. Use techniques like snap-fit joints, which facilitate easy assembly and disassembly, enhancing the product’s end-of-life recyclability and reducing waste.

- Material Selection for Recycling: Increase using a single material or compatible composites in parts manufacturing. This simplifies the recycling process, making it more efficient and less costly.

- Innovative Manufacturing Techniques: Opt for advanced manufacturing technologies like laser cutting, which are generally more precise and waste less material than traditional methods. Avoid processes that rely heavily on water and chemicals, reducing the environmental impact.

Some of the essential tools and techniques that can help implement sustainable practices include:

- CAD tools: Improve design for material efficiency and ease of manufacturing.

- Finite Element Analysis (FEA): Evaluate designs for performance and durability before their production.

- Additive Manufacturing (AM): Using 3D printing to enable material reuse and prevent waste.

- Process simulation tools: Evaluate energy consumption and impact on the environment of manufacturing.

A Case in Point: Applying DFM in Sheet Metal Chassis

Cost-effectiveness and efficiency are essential for the cut-throat realm of manufacturing and New Product Design. Design for Manufacturing (DFM) methods are crucial for sheet metal enclosures to attain these goals. By incorporating DFM techniques at the start of the designing phase, sheet metal fabricators can optimize shop floor efficiency, minimize waste, and develop top-notch products.

Here are the essential DFM methods tailored explicitly for sheet metal chassis:

Material Selection

- Standard Sheet Sizes: Use standard sheet sizes to cut down resource expenses and minimize scrap.

- Material Choices:

- Stainless steel for rust prevention.

- Aluminum for lightweight applications.

- Steel for resilience and long-term durability.

- Thickness Compatibility: Ensure the material thickness is compatible with the machinery’s cutting and bending capacity.

Enhancing Cutting Procedures

- Nesting: Arrange parts to reduce scrap and optimize material usage.

- Laser/Plasma Cutting: Avoid complex profiles to maintain consistent edge quality and speed up the cutting process.

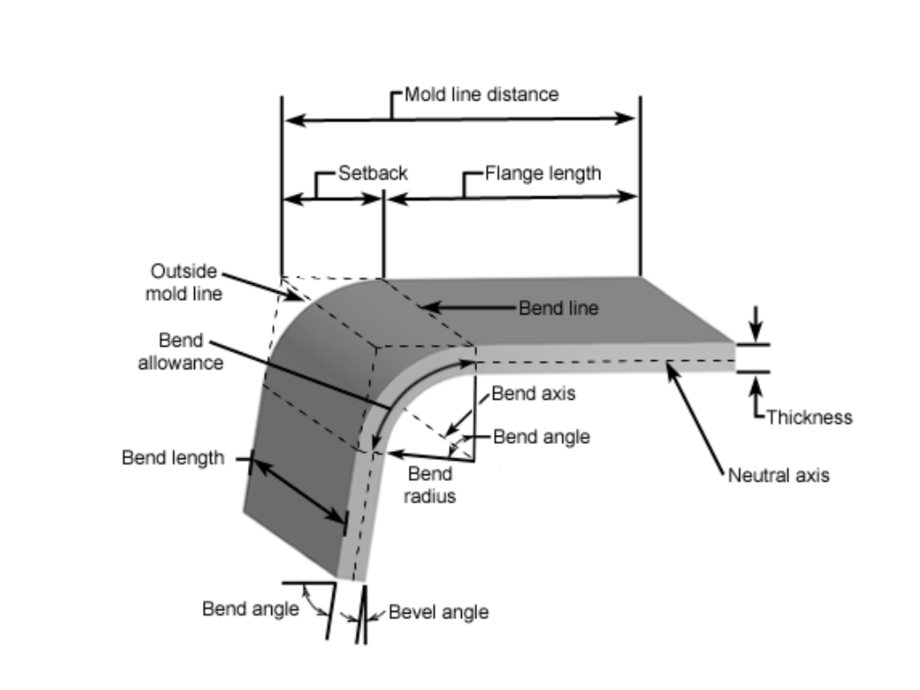

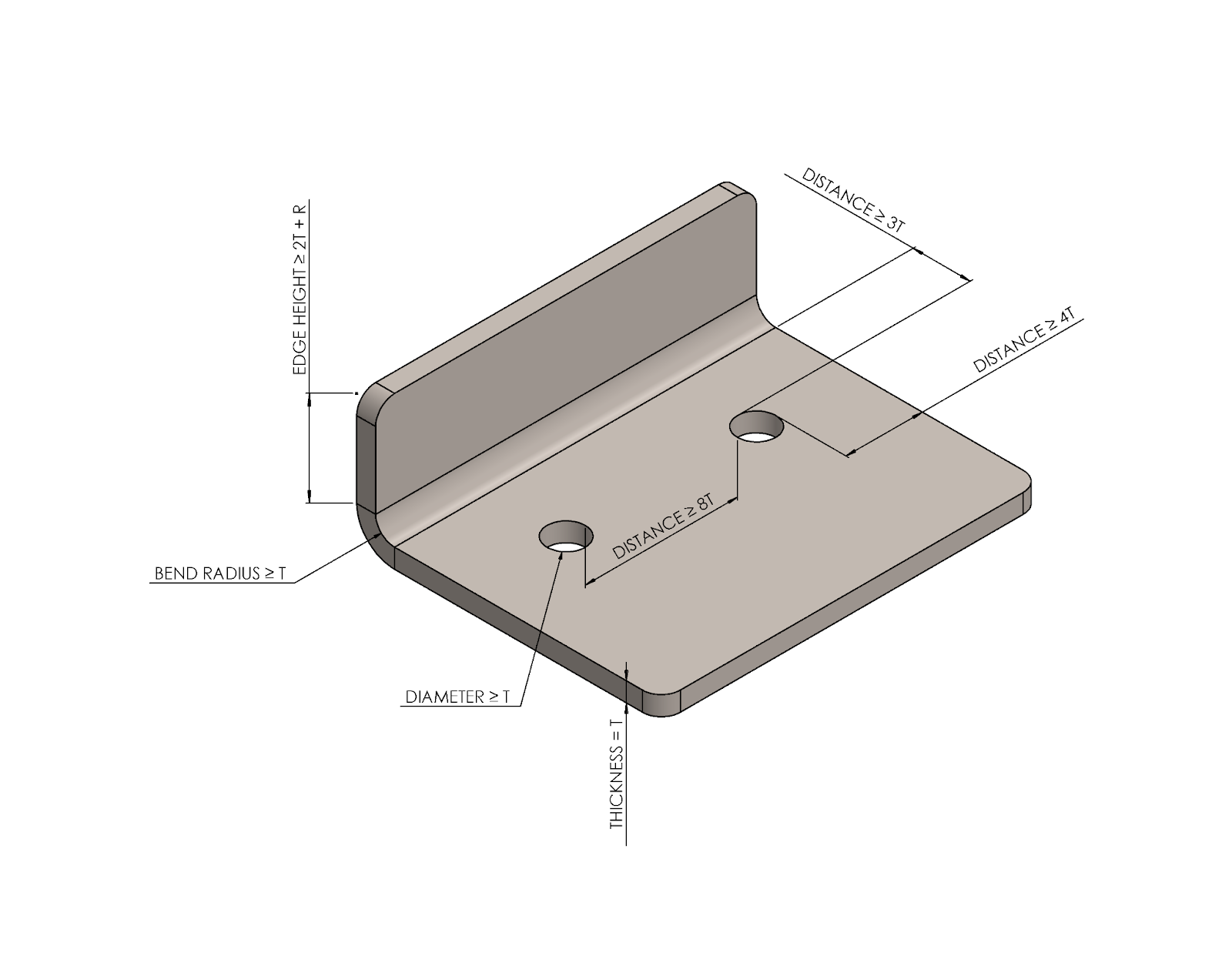

Standardization of Bend Radii

Image credit: https://www.custompartnet.com

- Forming and Bending: Utilize consistent bend radii to minimize the need for multiple tools.

- Springback Consideration: Account for the material’s rebound potential after bending.

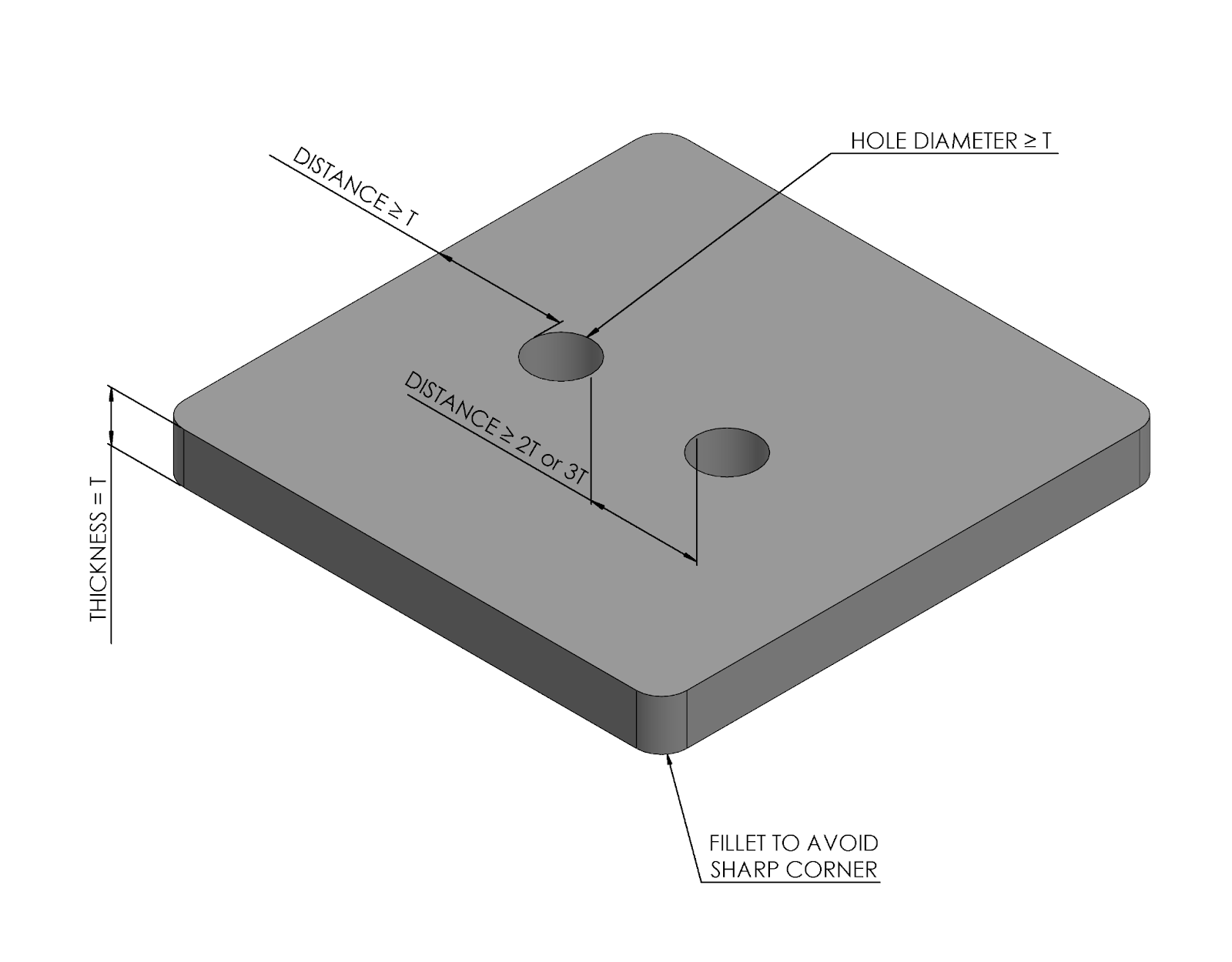

- Edge Design: To prevent material breakage, avoid placing steep curves near edges or holes, ensuring holes or edges are at least twice the material thickness.

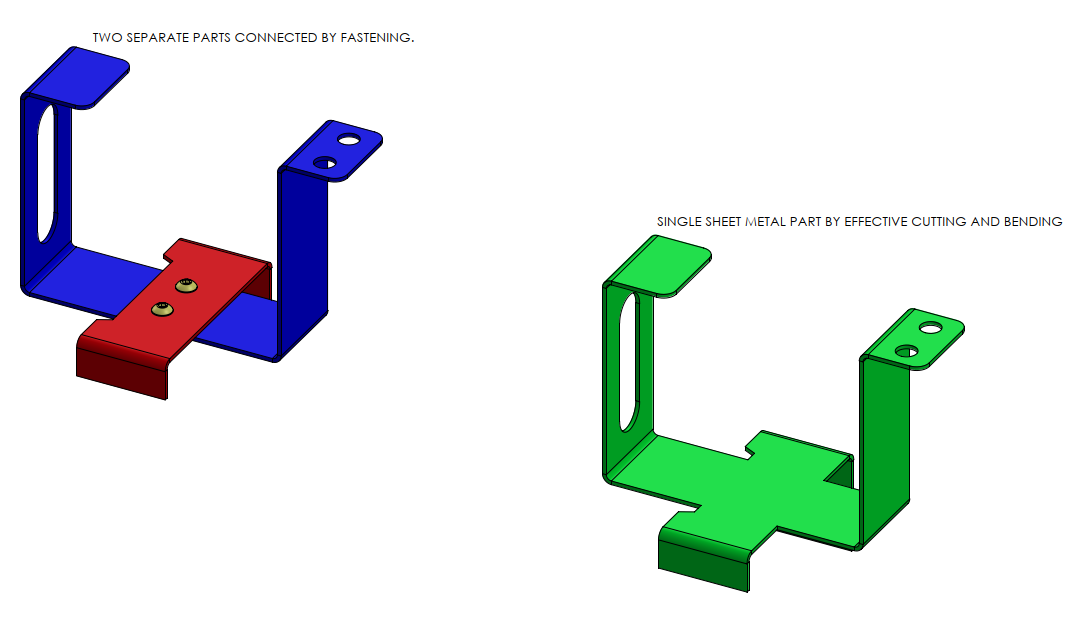

Simplification of Design Geometry

- Shape Simplification: Use straightforward, consistent shapes for easier cutting, bending, and assembly.

- Feature Reduction: Minimize the number of curves and openings to simplify manufacturing.

Modeling and Evaluation

- Rapid Prototyping: Use laser equipment for rapid prototyping to validate manufacturability.

- Production Modeling: Employ CAD software to simulate the curving, cutting, and manufacturing processes.

- Pilot Production: Conduct small-scale production runs to identify and resolve manufacturing issues.

Minimising Material Wastage and Weight

- Weight-Reducing Cutouts: Implement strategically placed cutouts to reduce weight without compromising durability.

- Ribbing for Sturdiness: Use ribs or arches instead of thickening materials to enhance structural integrity.

Assembly Design

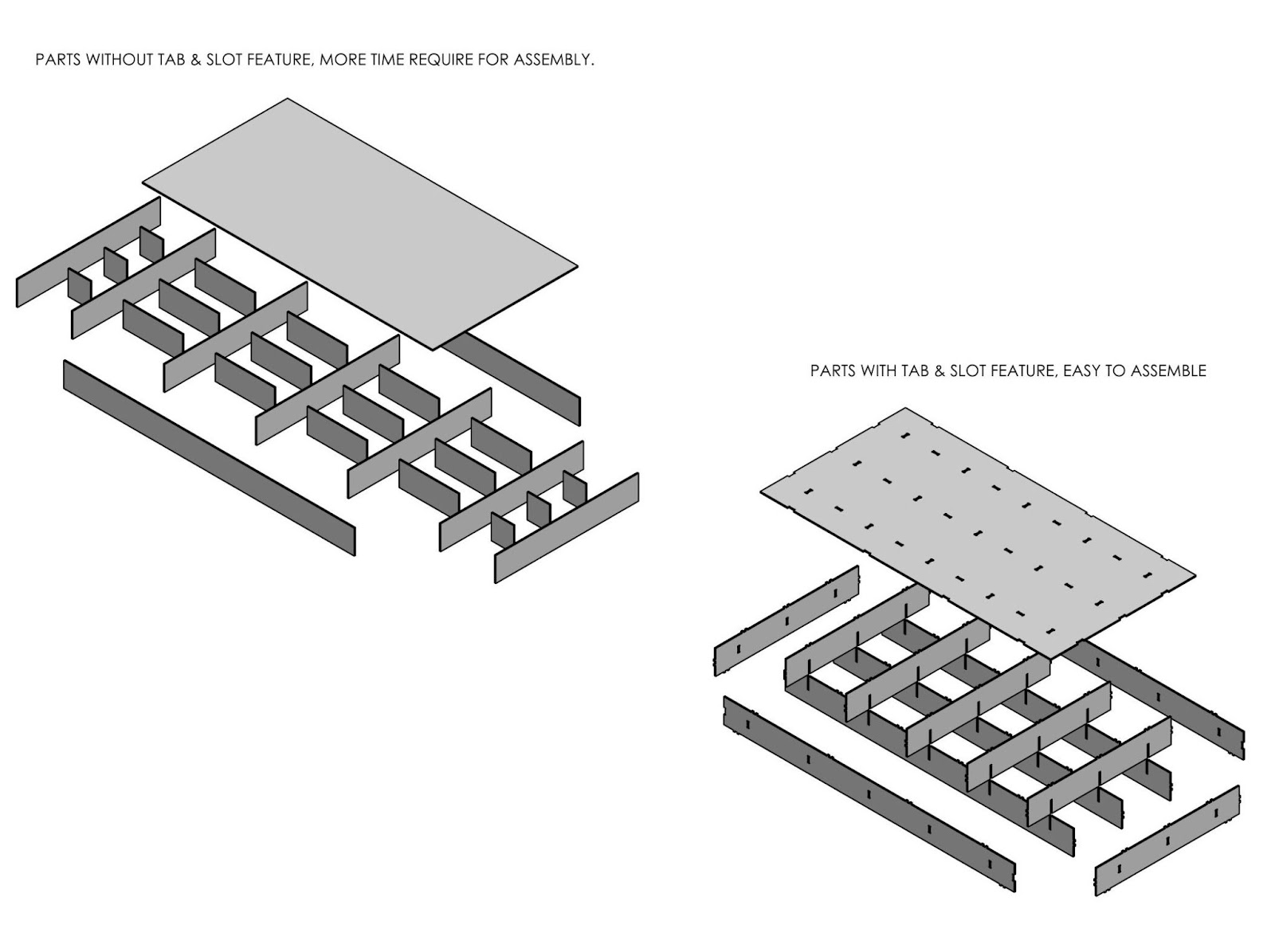

- Ease of Assembly: Design components that are easy to assemble, using identical pieces that align during assembly.

- Integrated Architecture: Break down complex chassis into simpler, more manageable sections for assembly.

Standardization of Components

- Uniform Components: Standardize connectors and fasteners to streamline procurement.

- Reusable Features: Limit customization by reusing common design elements like

- anchoring points across multiple designs.

Alternative Joining Techniques

- Reduce Welding and Fastening: Minimize labor-intensive welding and fastening to cut labor costs and assembly time.

- Innovative Joining Methods: Consider riveting, clinching, or adhesive bonding as alternatives to welding.

- Pre-Drilled Holes: Design for pre-drilled holes to accommodate standard fasteners, simplifying assembly.

Work with ZetaCADD to Meet Your DFM Goals

Design for Manufacturability (DFM) is not just a tool for optimizing production—it’s a critical strategy for the future of manufacturing. By applying DFM principles, companies reap significant cost savings and quality improvements and step forward in their commitment to sustainability.

As we’ve explored, integrating DFM with eco-friendly practices reduces manufacturing processes’ environmental footprint, promotes resource conservation, and supports global sustainability goals. Embracing DFM is not just about staying competitive; it’s about being a responsible manufacturer in a world where efficiency and environmental care go hand in hand. Begin implementing DFM in your projects now to witness its transformative effects.

If you’re looking to enhance your product designs with precision and sustainability in mind, ZetaCADD is your go-to partner. Specializing in DFM, we offer design services that ensure your projects are optimized for manufacturability from the start.

Contact us to learn more.