In industrial operations, asset longevity hinges on an organization’s ability to bridge the gap between legacy hardware and modern digital workflows. When a critical component reaches end-of-life (EOL) or the Original Equipment Manufacturer (OEM) no longer supports the product line, engineering leadership faces a technical crossroads. The decision is rarely a simple matter of replacement. […]

Digital transformation in manufacturing has changed the way the industry operates. Industry 4.0 has become a reality, and AI, simulation-based testing, predictive maintenance, data science, IoT-enabled smart manufacturing, and digital twin solutions are rapidly evolving in capability, accuracy, and scale. A digital-first data-driven ecosystem has replaced the linear, experience-driven system. This has helped manufacturers gain […]

Traditionally, engineering design fundamentals were about solving problems. But modern engineering design principles went through a shift from linear problem-solution mapping to holistic system-level problem solving. Modern engineering principles entail anticipating, defining and solving interconnected user needs. Here, technology plays an important role. Technology has reshaped engineering best practices and has redefined what a ‘good […]

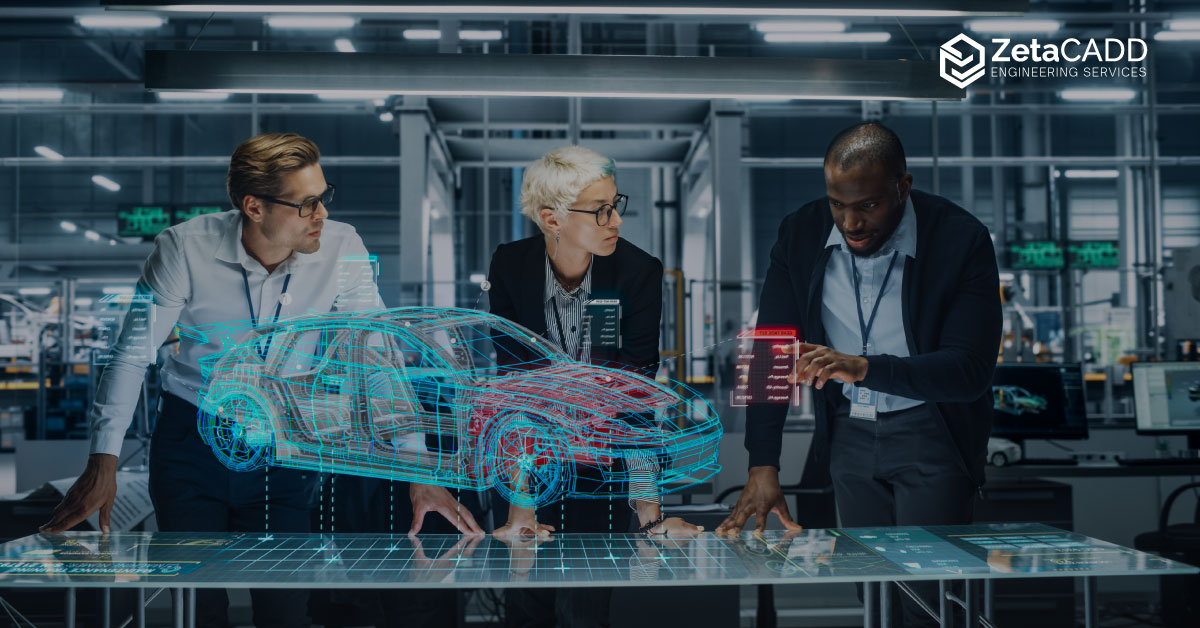

As global automation demand grows, the market for collaborative robots, popularly known as cobots, is projected to surpass USD 11.8 billion by 2030, at a CAGR of 31.6%. These robots are collaborating and working alongside humans and making operations safe and efficient. This shift places mechanical design engineering right at the center of how humans […]

Forward-thinking businesses are investing in sustainable product ecosystems more than ever before. Why? Because it helps them cut costs, stay compliant and strengthen their brand. It all starts at the drawing board, and makes mechanical design for sustainability a strategic imperative. Eco-friendly product design plays a decisive role in determining how prudently a product uses […]

For manufacturers, poor maintenance doesn’t just halt production; it triggers a chain reaction of unplanned downtimes, safety risks, financial losses, and even reputational risks. As a result, manufacturers are shifting from reactive (traditional) to proactive (digital twin mechanical maintenance) strategies driven by data and intelligent automation. Digital Twins Manufacturing is an advanced technology that enables […]

Large-scale construction projects are complex. They involve multiple teams, engineers, architects, vendors, and contractors. When multiple teams and stakeholders work together, it is essential that they all remain aligned, avoid conflicts, collaborate in real-time, and keep projects on track and within budget. BIM outsourcing services help AEC firms meet all these requirements for seamless project […]

Digital transformation is no longer a distant vision. Organisations today have already gone digital, embedded cloud platforms and are now stepping into the era of embedding automation and AI into their workflows. Companies want to adopt and accelerate tech to achieve greater precision, speed and strategic insight. For industries such as aerospace, automotive, construction, and […]

Businesses are prioritizing manufacturability and accuracy, and increasingly relying on engineering design outsourcing and advanced CNC programming services to improve manufacturability, reduce costs, and reduce cycle time without losing tolerances. Shorter cycle time means faster production and quicker time-to-market. However, in a bid to speed up the cycle, maintaining tolerances should not be neglected. CNC […]

Are you planning to outsource engineering design services from an offshore vendor? That’s a strategic choice that will help you save costs, get your products faster to market, get access to a global talent pool, the latest technology and tools and drive higher ROI. However, ROI is not guaranteed; many things can go wrong, and […]

Mechanical engineering outsourcing has become a common practice for the product design and manufacturing industry worldwide. According to the Mechanical Engineering Outsourcing analysis report, the industry is said to grow with a CAGR of 7% to 8% from 2025 to 2033, reaching around $85 billion in 2033. Some of the most common outsourced services include […]

If a product cannot be assembled easily, needs too many design iterations, and is not easy to scale, it is a nightmare for any business. Even when the product looks too good on paper, cost overruns and frequent downtimes are like the rude wake-up calls that must be taken seriously. Out of the many considerations […]

A good mechanical design is not just about good ‘look and feel’; it is also about good performance, ease of manufacture, and cost-efficiency. It includes a robust mechanical assembly design that enables smooth production and scalability. Other factors that must be taken into account are ease of maintenance, repair, functional integrity, etc. Even the best […]

Competition pushes manufacturers to do more with less. DFM uses manufacturing insights early in the design process and strategically creates smarter, simpler, and more cost-effective products, giving companies the edge they need to survive a competitive market space. What is DFM? DFM (Design for Manufacturing) is an engineering practice that focuses on the practical aspects […]

Businesses worldwide are looking to invest in smarter solutions and efficient ways to operate and get a higher return on investment (ROI). Better technology, automation, AI, skilled talent, efficient and reliable partners – the list is endless. Outsourcing Engineering design, drafting, and CAD conversion services is one such solution that has gained immense popularity across […]

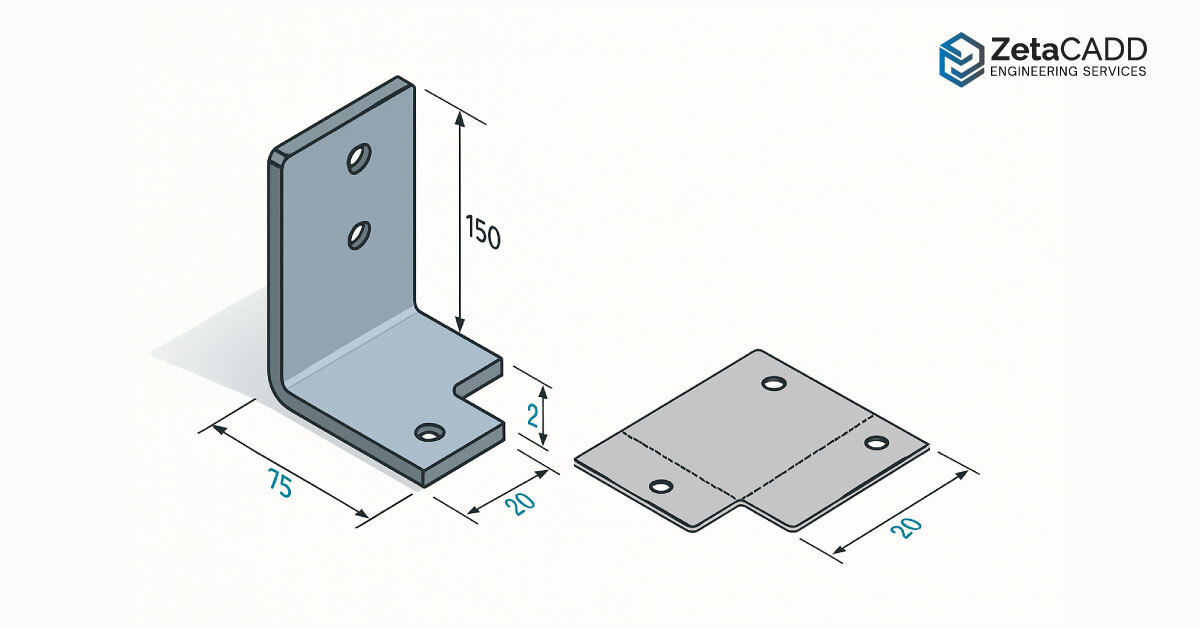

ZetaCADD is a provider of 3D sheet metal modeling services for clients around the globe. From manufacturing and automobiles to the heavy engineering and construction industry, our sheet metal design expertise has helped our clients optimize production and create lightweight, durable, and cost-effective products. How do we do this? It entails prioritizing the need for […]

CAD conversions have revolutionized the way projects are handled. Over the years, CAD conversions have progressed from 2D drafts and 3D models to highly sophisticated file formats that support immersive experiences and real-time collaborations. Technology has fuelled realistic visualizations and brought high precision and accuracy to the table. However, every project is different and has […]

Sustainability is no longer a luxury—it has become a guiding principle for businesses and designers seeking to create enduring, responsible spaces. Nowhere is this more apparent than in contemporary architecture, where eco-friendly practices are woven into every stage of craftsmanship. Millwork—encompassing wood-based fixtures such as paneling, molding, and cabinetry—is a core element in interior design, […]

Design for Manufacturability (DFM) is more than just a smart manufacturing strategy—it’s a vital step towards more sustainable and efficient production. By integrating DFM, companies can cut production costs by up to 50% while improving product quality and market readiness. DFM acts as a link between manufacturing and design, and by passing knowledge on limitations […]