How 3D Sheet Metal Design Ensures Optimised Production?

ZetaCADD is a provider of 3D sheet metal modeling services for clients around the globe. From manufacturing and automobiles to the heavy engineering and construction industry, our sheet metal design expertise has helped our clients optimize production and create lightweight, durable, and cost-effective products. How do we do this? It entails prioritizing the need for precision, using the right technology to enable effective collaboration, CNC machining, rapid prototyping, and more.

Any errors in sheet metal design and fabrication can lead to disruptions across the assembly and production lines. The need for precision is paramount, and any mistakes amount to delayed production, reiterations at every stage, and hence increased costs. To avoid such mistakes and optimize production, what should you do?

Partner with us. How does it help?

Visual clarity and real-time simulation:

Expert 3D sheet metal design allows all the stakeholders to view designs and understand the geometry, see how parts fit in real-world assemblies, and simulate fastening methods. Why are visual clarity and real-time simulation of such grave importance? Let’s understand the how and why as we delve into the 3D Sheet metal design and simulation process.

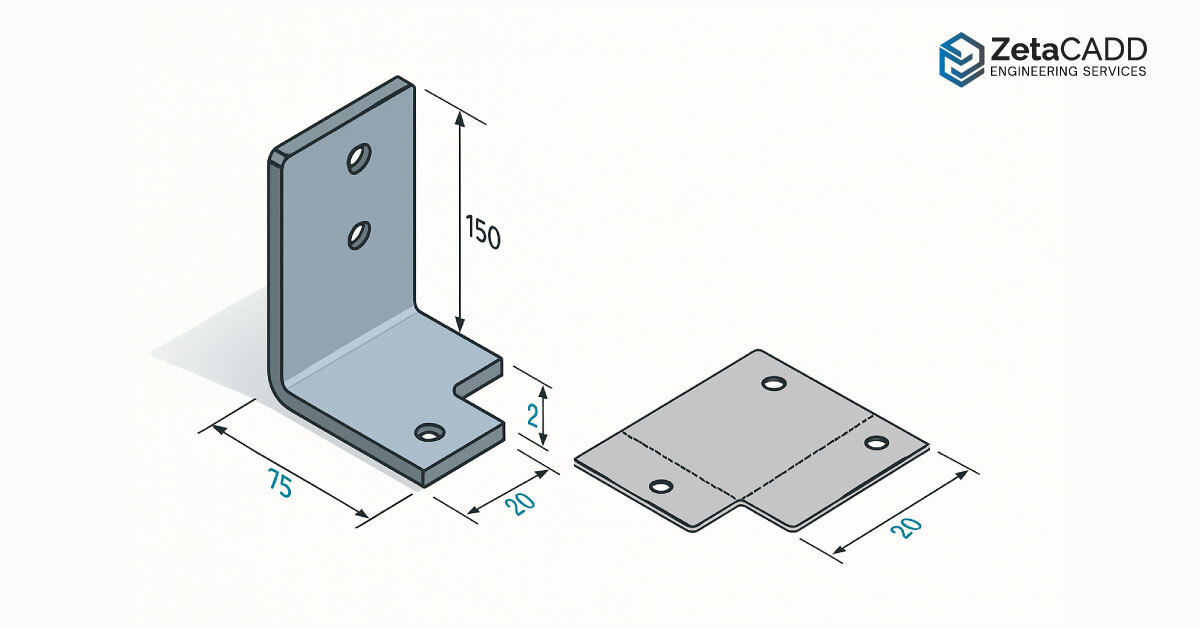

Accurate Flat Pattern Development

Everything starts with a flat pattern. It is like a blueprint that tells the fabricator exactly where to bend, punch, and cut. It sets the foundation for 3D design and simulations. Flat pattern design can be tedious and time-consuming. However, using 3D tools to automate flat pattern generation makes the process quick and efficient and eliminates the possibility of manual errors.

- Built-in sheet metal rules define material properties, thickness, radii, and other parameters.

- K-factor integration determines how the material behaves in the real world under various circumstances.

- Using the right software and expertise, the bend allowance is calculated and adjusted for the flat pattern.

- Flat patterns are linked to 3D simulations for stress testing, interference checking, and manufacturability analysis.

Improved Collaboration and Communication

A 3D information-rich model becomes a single source of reference for all stakeholders, like the designers, engineers, fabricators, contractors, and manufacturers. All updates happen in real time, and the problem of data redundancy or errors due to multiple information sources is mitigated. All stakeholders get access to exploded views, can view and add annotations, and are on the same page with a clear understanding of the design.

Result?

Bridging the gap between design intent and production outcomes

Cloud collaboration and seamless communication across teams help optimize the project execution process. It fosters better teamwork, keeps all parties updated, and closes the gap between design intent and the production outcome.

Early Detection of Manufacturability Issues

All designs are not production-ready. Once a 3D model for sheet metal design is ready, it is simulated and tested for manufacturability. This process is known as the DFM (design-for-manufacturability) check. The process entails:

- 1. Minimum Bend Radius

- 2. Material Thickness

- 3. Bend Relief and Corner Relief

- 4. Hole & Feature Placement

- 5. Notches, Tabs & Slots

- 6. Tool Access & Assembly Clearance

- 7. Avoiding Over-Complex Features

- 8. Tolerance Feasibility

DFM checks help evaluate the designs early on and ensure that the design is ready for manufacturing- meaning that the product is manufactured easily, accurately, and economically using available processes and tools.

Integration with CNC and CAM Systems

The production process involves laser cutting, nesting, press brake programming, etc. 3D designs are directly integrated with CNC (Computer Numerical Control) and CAM (Computer-Aided Manufacturing) systems to automate these processes and make them highly accurate and efficient.

High-precision 3D sheet metal design eliminates translation errors and ensures optimal use of resources, thus making the process from design to product efficient and cost-effective.

Rapid Prototyping and Iteration

Rapid prototyping, testing, and iterations help optimize designs before they go for mass production or manufacturing. 3D sheet metal modeling and simulation experts use parametric modeling tools that make design edits faster. Digital prototyping and simulation-based testing are cost-effective compared to repeated prototyping and testing. Using 3D tools, designs are virtually optimized for maximum output and best design features before the product is prototyped, thus reducing the time and money required to take the product to market.

Conclusion

3D Sheet metal designs tell every person and tool across the board what to do, how to do it, and how to check if it is done right. They present numerous tangible and intangible benefits, as discussed in the article.

The benefits can be summed up as:

- Optimised design

- Faster production cycle

- Improved collaboration and communication

- Less chance of errors

- Optimised use of materials

- Lower CAPEX/OPEX

And hence an optimized production.

Partnering with the right 3D sheet metal design services brings significant value to manufacturing. It is a strategic choice that shapes modern production workflows. For businesses aiming to stay competitive and efficient, embracing sheet metal design outsourcing is a practical and forward-thinking choice.