Reverse Engineering vs. Redesign: When to Replicate and When to Innovate

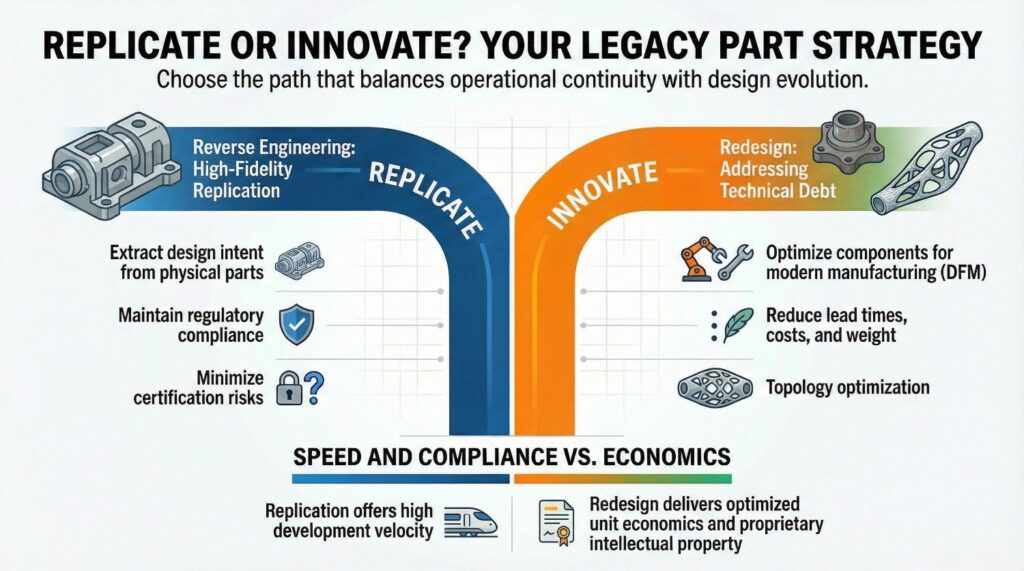

In industrial operations, asset longevity hinges on an organization’s ability to bridge the gap between legacy hardware and modern digital workflows. When a critical component reaches end-of-life (EOL) or the Original Equipment Manufacturer (OEM) no longer supports the product line, engineering leadership faces a technical crossroads.

The decision is rarely a simple matter of replacement. It is a strategic choice between the high-fidelity replication of an existing asset and a fundamental redesign to improve performance.

For those overseeing Maintenance, Repair, and Overhaul (MRO) or new product development, evaluating these two paths requires a focus on technical risk, unit economics, and Geometric Dimensioning and Tolerancing (GD&T) requirements.

High-Fidelity Replication: The Mechanics of Reverse Engineering

Reverse engineering is a disciplined metrology workflow focused on extracting design intent from a physical part. In highly regulated sectors such as aerospace, power generation, or medical device manufacturing, replication is often the most viable strategy to maintain compliance without the costs associated with extensive re-validation or regulatory re-certification.

Technical Requirements for Industrial Replication

Executing a successful “Scan-to-CAD” project requires more than surface-level data. It demands a rigorous process to account for wear and tear on the original sample.

- Metrology-Grade Data Acquisition: Utilizing structured light or laser scanners provides the point cloud density required for high-precision components. For critical interfaces, accuracy must reach ±0.002” or better to ensure proper fitment within an existing assembly.

- Material Characterization: Beyond geometry, the metallurgy must be verified. Professional reverse engineering includes Optical Emission Spectroscopy (OES) for chemical composition analysis and hardness testing to identify specific heat treatment requirements.

- Capturing Design Intent: A scan of a worn part represents “as-is” geometry. The engineering task is to convert this data into a parametric CAD model that reflects “as-designed” specifications, correcting for deformations, corrosion, or previous manufacturing errors.

Design Optimization: Addressing Technical Debt through Redesign

Redesigning a legacy component is a proactive strategy to eliminate technical debt. Many older parts were designed for manufacturing processes, such as sand casting or manual milling, that are now inefficient. Replicating an outdated design often forces an organization to accept high lead times and inflated costs. Redesigning allows the part to be optimized for current Design for Manufacturability (DFM) standards.

Strategic Drivers for Redesign

- Manufacturing Conversion: Converting a complex casting into a multi-part weldment or a 5-axis CNC machined component can significantly reduce the Bill of Materials (BOM) cost and lead time.

- Topology Optimization and FEA: Modern Finite Element Analysis (FEA) allows engineers to simulate operational stresses. This data enables topology optimization, where material is removed from low-stress zones to reduce weight without compromising structural integrity.

- Part Consolidation: Through Design for Additive Manufacturing (DfAM), it is often possible to consolidate an entire sub-assembly into a single integrated component, reducing assembly labor and eliminating failure points like fasteners or gaskets.

Decision Framework for Engineering Stakeholders

Choosing between these two methodologies requires a balanced assessment of operational goals and regulatory constraints.

| Engineering Metric | Reverse Engineering (Replicate) | Redesign (Innovate) |

| Compliance Risk | Minimal: Usually qualifies as a like-for-like replacement. | Higher: May require new testing and certification. |

| Development Velocity | High: Shortens the design cycle by using proven geometry. | Moderate: Requires validation through simulation and prototyping. |

| Unit Economics | Static: Costs remain tied to legacy manufacturing logic. | Optimized: Reduced through modern DFM and production methods. |

| Structural Integrity | Proven: Relies on historical field performance. | Validated: Verified through FEA and stress testing. |

Intellectual Property and Interoperability

From a strategic perspective, risk management must include a review of intellectual property. Reverse engineering for the purpose of repair and maintenance of a lawfully acquired asset is a standard industrial practice. However, redesign offers a distinct advantage by allowing an organization to develop its own proprietary IP. By improving the functional performance of a component, a company can create a unique competitive position while ensuring interoperability with existing systems.

Criteria for Selecting a Technical Service Partner

A service partner must offer more than just hardware. They should act as a technical consultant capable of evaluating the lifecycle of the component. When vetting a partner, prioritize firms that demonstrate:

- Quality Management Systems: Look for ISO 9001 or AS9100 certifications to ensure traceability and data integrity throughout the reconstruction process.

- Multidisciplinary Expertise: The provider should be proficient in both metrology and advanced engineering simulation (FEA/CFD). This ensures they can pivot between replication and optimization as the project requires.

- Native CAD Deliverables: Ensure the final output is a fully featured, parametric model in your preferred software, such as SolidWorks, NX, or Creo, rather than a non-editable STEP file or STL mesh.

Balancing Operational Continuity with Design Evolution

The choice between replication and innovation represents a critical juncture in asset lifecycle management. Reverse engineering provides the necessary continuity for maintaining operational stability, while redesign offers a strategic path to leverage modern manufacturing for improved performance. Navigating this choice requires a deep understanding of both legacy constraints and the possibilities afforded by modern engineering tools.

At ZetaCADD, we specialize in this technical intersection. Our team provides the metrology-grade precision and DFM expertise required to transform physical hardware into high-integrity digital assets.

Whether your project demands high-fidelity replication for a legacy assembly or a complete redesign for optimized production, we offer the technical consultation and parametric modeling support necessary to achieve your operational goals. Reach out to our engineering team to evaluate the most effective path for your next component project.