CAE Services

- Home

- CAE Services

Engineering Precision for Optimal Performance

Leverage our cutting-edge Computer Aided Engineering (CAE) capabilities to enhance your engineering processes. Our services, from structural analysis to dynamic simulations, ensure robust, optimized, and efficient designs.

Empower Your Designs with Expert CAE Analysis

Structural Analysis

Multibody Dynamics

Fatigue/Durability

Thermal Analysis

Dynamic & Vibrational Analysis

Why Our CAE Services Stand Out?

Cutting-Edge Simulation Capabilities

Harness our state-of-the-art CAE tools and software for unparalleled accuracy in simulations, enabling complex analyses like finite element and computational fluid dynamics that are critical to advanced engineering projects.

Deep Technical Expertise

Our team consists of certified engineers and industry experts specialized in CAE applications across various sectors, including aerospace, automotive, and consumer electronics, ensuring that your projects benefit from the deepest technical knowledge and insights.

Custom Engineering Solutions

We go beyond standard analyses to develop custom solutions tailored to your specific challenges and requirements, integrating our services into your design process to enhance performance, reliability, and cost-effectiveness.

Advanced Material and Process Analysis

Leverage our advanced understanding of material science and engineering processes to predict and optimize how materials behave under different stresses and environments, crucial for developing robust and durable products.

Comprehensive Service Integration

Our CAE services are fully integrated with your engineering and design teams to streamline workflows and data transfer, enhancing collaboration and reducing time to market for new innovations.

Optimization and Innovation

We utilize CAE not just for validation but as a tool for innovation and optimization, enabling design improvements that are both resource-efficient and performance-driven, which is essential in competitive marketplaces.

Optimize Your Engineering Designs with Precision CAE Analysis

Reach out to explore how our CAE services can refine and perfect your projects.

Our industries

-

Metal Fabrication

-

Machine Manufacturing

-

Heavy Engineering

-

Automobile Industry

-

Oil & Gas Industry

-

Construction

-

Process Industry

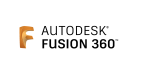

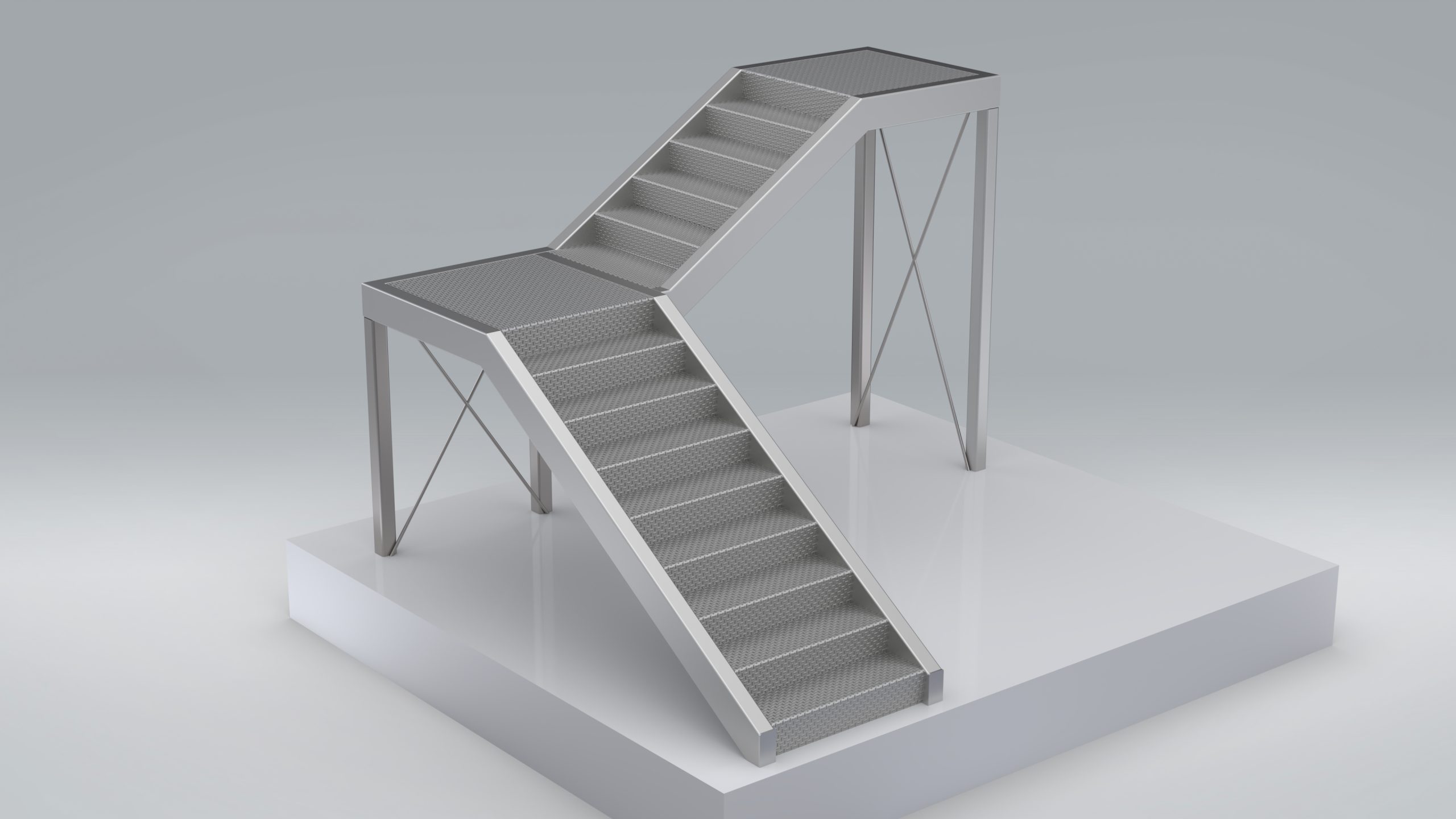

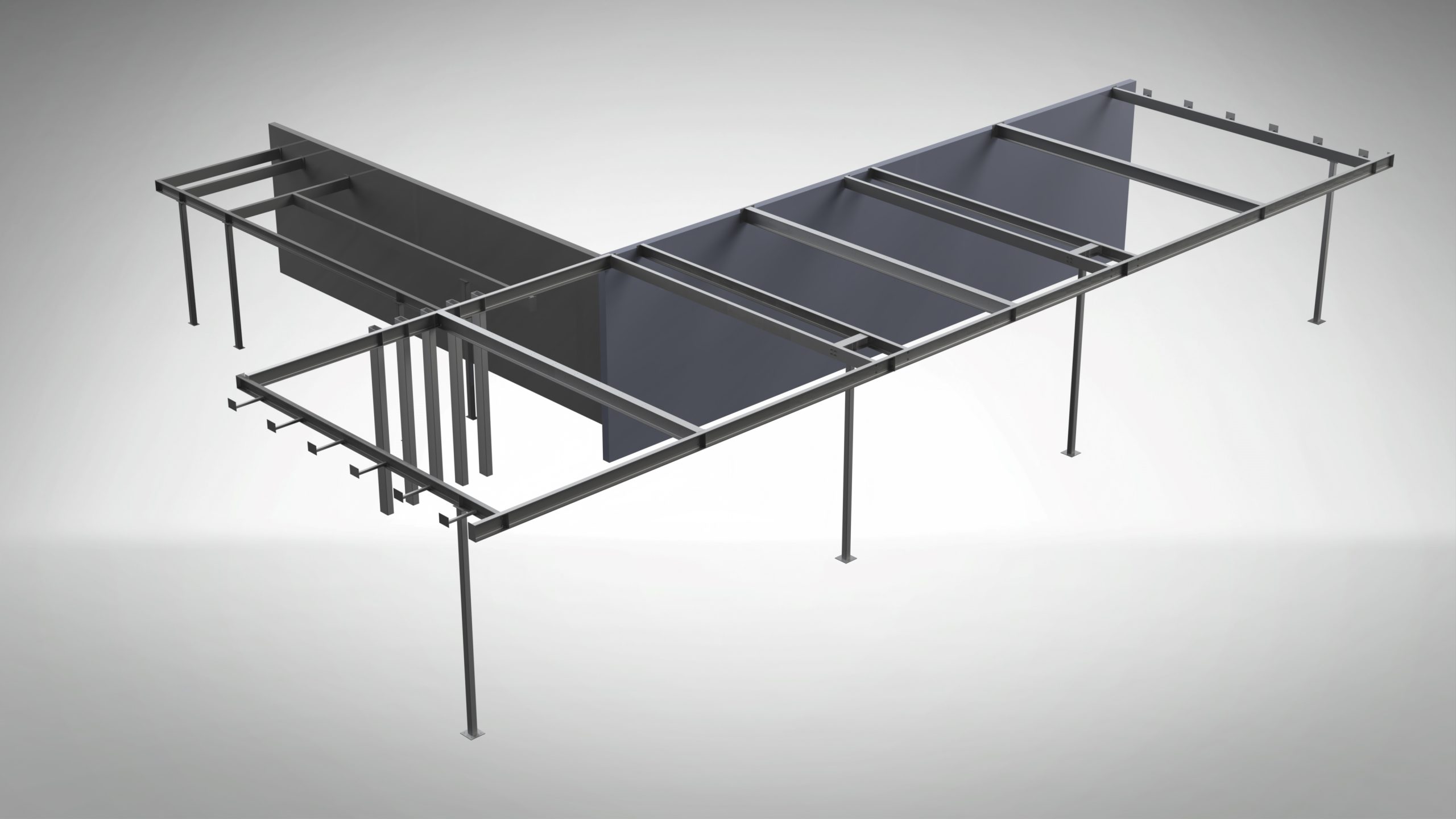

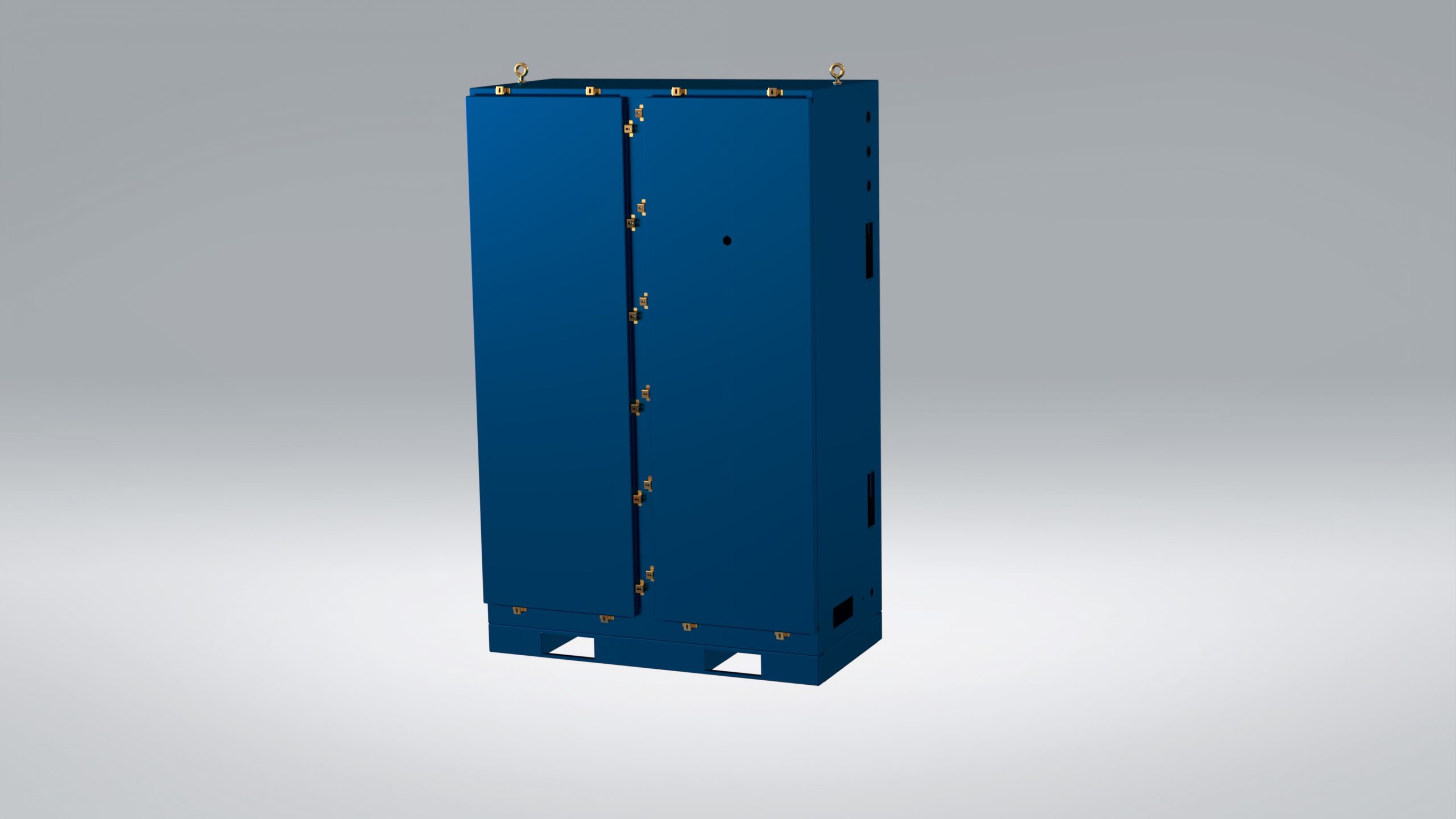

Our Recent Works

- All

- CAD Modelling Detailing

- Sheet Metal Design

- Structural Design

- Reverse Engineering

- Millwork Shop drawing

Testimonials

Courtney Henry / Customers in U.S.A

Marry Tonheim / Customers in UK

Anna Richmond / Customers in SA

Outsource Engineering Services for

Agile, Innovative, and Robust Solutions

Operational Brilliance, Cost-Effective

Your overheads don't just reduce; they transform into investments for future breakthroughs.

Fluid Resource Strategies

We offer not just flexibility but adaptability, ensuring you're always ahead of the curve.

Speed Meets Success

Fast-tracking isn't just about pace; it's about precision. Your key projects become our milestones.

No Purse Strings Attached

Dive into a pool of genius minds and state-of-the-art technologies, all without the commitment of investment

Introduce Our Projects

Software development outsourcing is just a tool to achieve business goals. But there is no way

to get worthwhile results without cooperation and trust between a client company.

Our Latest Experience

Read Most

Frequent Questions

Finite Element Analysis (FEA) allows for detailed visualization of where structures bend or twist, and indicates the distribution of stresses and displacements. FEA helps predict the behavior of products affected by real-world forces, improving product design and reliability.

CFD consulting provides insights into fluid flows and heat transfer in and around your products. This analysis is crucial for optimizing processes and improving product performance and safety.

Dynamic analysis benefits projects that involve complex movements, mechanical stresses, and interactions under operational conditions, such as machinery, vehicles, and structural components.

Our thermal analysis services evaluate temperature distribution and heat transfer within and across components, crucial for managing thermal loads and preventing overheating in product designs.

We use validated models and state-of-the-art software, combined with rigorous testing and verification procedures, to ensure our simulations accurately reflect real-world scenarios.

Yes, integrating our CAE services early in the design process can significantly enhance design robustness, allowing for early detection and mitigation of potential issues.

Our fatigue analysis helps predict the life expectancy of a product under repeated stress, allowing for the design of more durable and reliable products.

CAE services provide critical insights that facilitate the refinement of designs, enhancing performance, reducing material costs, and achieving compliance with safety standards.

services?

We serve a wide range of industries, including automotive, aerospace, electronics, and consumer goods, where precision engineering is critical.

Our delivery timelines vary based on the complexity of the analysis but are optimized for efficiency to meet project deadlines without sacrificing detail or accuracy.