Dynamic & Vibrational Analysis

- Home

- CAE Services

- Dynamic & Vibrational Analysis

Enhance System Reliability with Advanced Dynamic and Vibrational Analysis

Maximize the performance and durability of your mechanical systems with our dynamic and vibrational analysis services. Utilizing state-of-the-art simulation tools, we assess and mitigate risks associated with vibrations and dynamic forces, ensuring your systems are optimized for stability and longevity.

Tools We Use

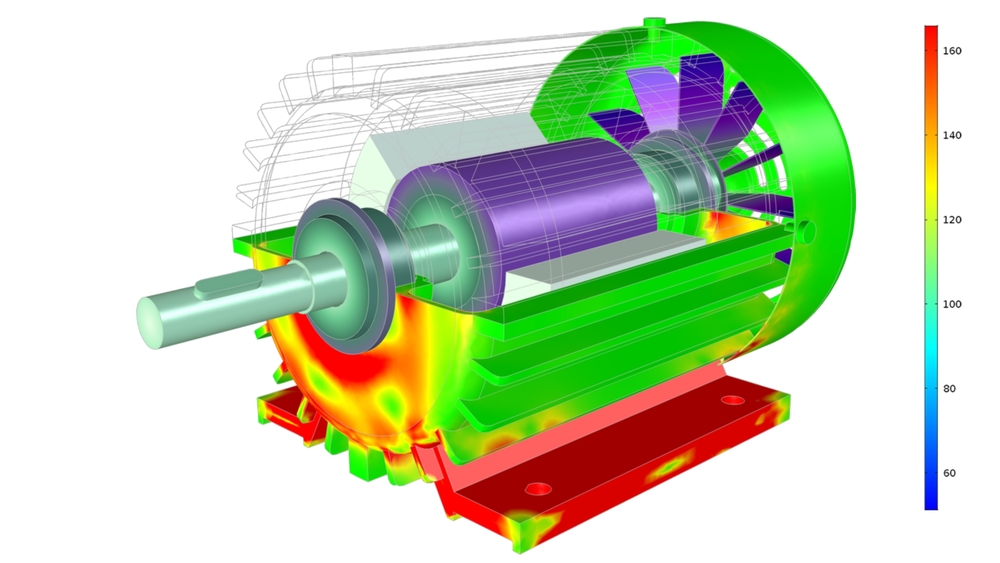

FEA Analysis for Optimal Dynamic Performance

Our dynamic and vibrational analysis services are designed to address the challenges posed by unwanted vibrations and dynamic forces in mechanical systems. By identifying potential issues early in the design process, we help you develop solutions that improve product life, safety, and functionality.

Vibration Analysis and Mitigation

Conduct detailed analyses to identify vibration frequencies and amplitudes that could lead to fatigue or failure and develop strategies to mitigate these effects through design modifications or damping solutions.

Modal Analysis

Perform modal analysis to determine the natural frequencies and mode shapes of a system, which are crucial for predicting how it will respond to external and operational vibrations.

Harmonic Response Analysis

Analyze the response of your systems to harmonic forces, such as those generated by engines and rotating machinery, to ensure stability and prevent resonance.

Random Vibration Analysis

Evaluate the impact of random vibrations, such as those from environmental sources or operational variability, to assess the likelihood of structural failure and design appropriate countermeasures.

Shock and Transient Analysis

Investigate how your systems respond to transient and shock loads. This is essential for applications in sectors like aerospace and defense, where equipment must withstand sudden and extreme forces.

Damping Solutions Development

Design and optimize damping systems that effectively reduce vibrations, enhancing system performance and extending the lifespan of your equipment.

Our industries

-

Metal Fabrication

-

Machine Manufacturing

-

Heavy Engineering

-

Automobile Industry

-

Oil & Gas Industry

-

Construction

-

Process Industry

CAD conversion Process

The CAD conversion process at ZetaCADD involves a meticulous approach from physical or outdated designs to accurate and editable digital CAD files.

Consultation

Our technicians consult with clients and try collecting as much information about the project.

Quotation

After the scope of the project is understood, our experts evaluate and offer a price quote.

Feedback & Reviews

To prevent any last-minute changes, Polosoft prefers to get client input at every stage.

Delivery

Final drafts are checked by our professional team of quality analysts.

Talk to Our FEA Experts

Testimonials

Courtney Henry / Customers in U.S.A

Marry Tonheim / Customers in UK

Anna Richmond / Customers in SA

Read Most

Frequent Questions

Vibrational analysis is crucial because excessive vibrations can lead to material fatigue, premature failure, noise issues, and operational inefficiencies. By understanding and controlling vibrations, we ensure that systems are safer, more reliable, and have a longer service life.

This analysis helps engineers identify and address potential design flaws that could affect stability and functionality. By optimizing designs based on dynamic and vibrational insights, products are made more robust and compliant with performance specifications.

We utilize advanced simulation software, such as ANSYS, MSC Nastran, and Abaqus, for dynamic and vibrational analysis, which allows for precise and comprehensive assessments.

Absolutely, our services are applicable to a wide range of industries, including automotive, aerospace, manufacturing, construction, and electronics, where understanding and controlling dynamics and vibrations are critical.

We ensure accuracy by calibrating our models against experimental data and following best practices in simulation, backed by the deep expertise of our analysts who interpret results considering real-world conditions.

Turnaround times can vary based on the complexity of the project and the specific requirements, but we strive to deliver initial findings and actionable insights within a few weeks of project initiation.