Thermal Analysis

- Home

- CAE Services

- Thermal Analysis

Optimize Product Performance with Advanced Thermal Analysis

Ensure the reliability and efficiency of your products under varying thermal conditions with our comprehensive thermal analysis services. Utilizing advanced simulation tools, we assess heat transfer issues and temperature impacts to enhance product design and ensure operational safety.

Tools We Use

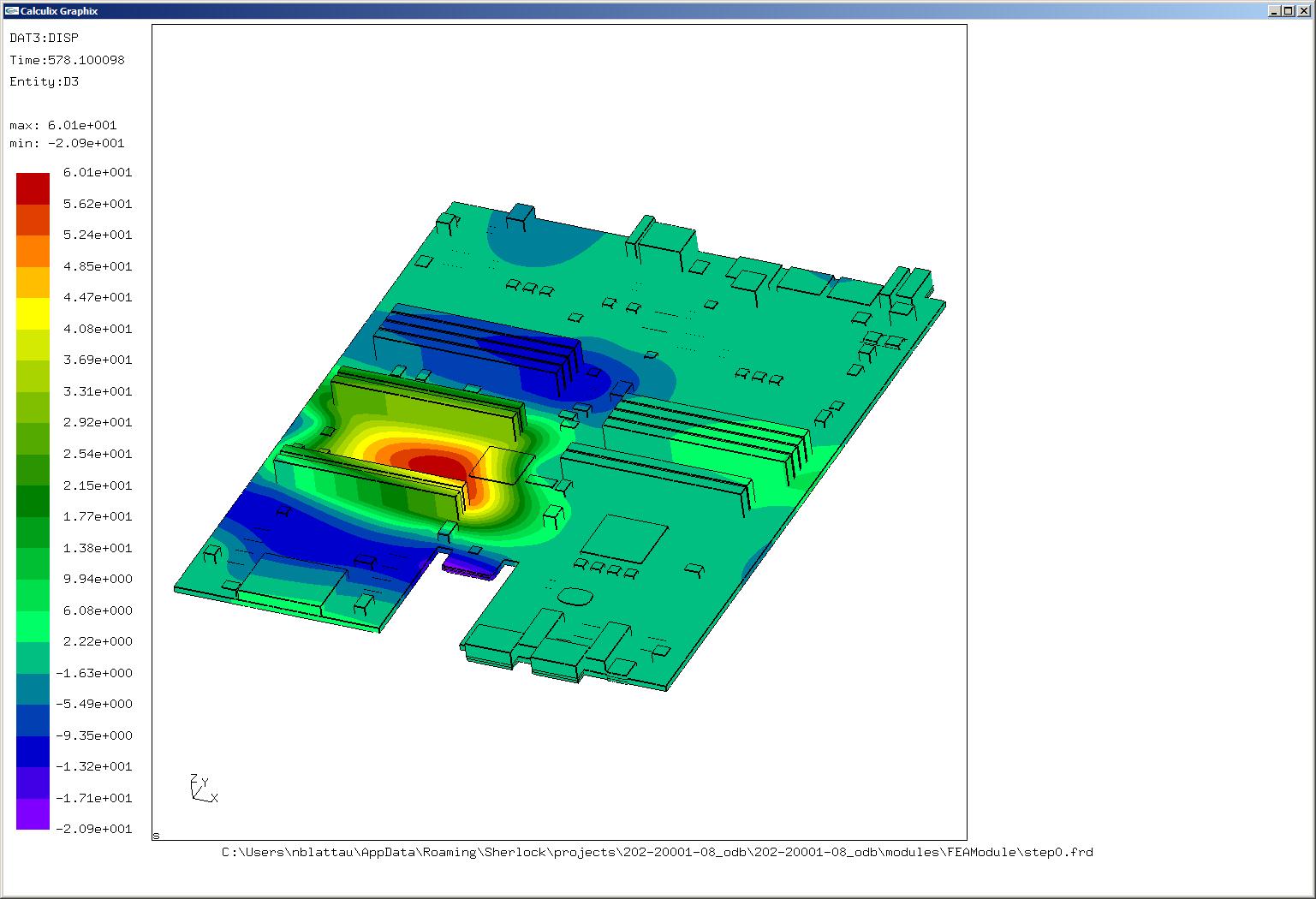

Thermal Simulations for Enhanced Design and Safety

Our thermal analysis services provide critical insights into the thermal behaviors of products and systems, enabling engineers to predict thermal responses and optimize designs. From electronics cooling to high-temperature industrial processes, our analyses help you manage and mitigate thermal risks.

Heat Transfer Analysis

Conduct simulations to evaluate conduction, convection, and radiation heat transfer within and between components, ensuring that products can manage heat effectively under operational stresses.

Thermal Stress Evaluation

Analyze the effects of temperature changes on material stress and deformation, helping to prevent thermal fatigue and structural failures in critical applications.

Cooling System Design

Design and optimize cooling systems to effectively manage and dissipate heat in products ranging from consumer electronics to automotive engines and aerospace components.

Temperature Distribution Studies

Map temperature distributions across components and assemblies to identify hot spots and areas of potential thermal improvement for better performance and reliability.

Coupled Thermal-Structural Analysis

Perform coupled thermal-structural analysis to understand the interplay between temperature fields and structural integrity, crucial for designing components subjected to extreme thermal environments.

Environmental Impact Simulations

To ensure robust designs across all expected operating conditions, simulate the environmental impact on systems, including solar loading, ambient temperature variations, and airflow.

Our industries

-

Metal Fabrication

-

Machine Manufacturing

-

Heavy Engineering

-

Automobile Industry

-

Oil & Gas Industry

-

Construction

-

Process Industry

CAD conversion Process

The CAD conversion process at ZetaCADD involves a meticulous approach from physical or outdated designs to accurate and editable digital CAD files.

Consultation

Our technicians consult with clients and try collecting as much information about the project.

Quotation

After the scope of the project is understood, our experts evaluate and offer a price quote.

Feedback & Reviews

To prevent any last-minute changes, Polosoft prefers to get client input at every stage.

Delivery

Final drafts are checked by our professional team of quality analysts.

Talk to Our Thermal Analysis Experts

Testimonials

Courtney Henry / Customers in U.S.A

Marry Tonheim / Customers in UK

Anna Richmond / Customers in SA

Read Most

Frequent Questions

Thermal analysis is essential across many industries, including aerospace, automotive, electronics, manufacturing, and energy, where thermal management is critical to product safety and functionality.

By identifying thermal vulnerabilities early in the design process, thermal analysis allows for adjustments that enhance material selection and structural design, thus extending the product's operational life.

We use leading CAE tools such as ANSYS Fluent, COMSOL Multiphysics, and Autodesk CFD to perform detailed and accurate thermal simulations.

Yes, thermal analysis often complements other analyses, such as structural, fluid dynamics, and electromagnetics, to provide a comprehensive overview of a product’s performance under realistic operational conditions.

We ensure model accuracy through calibration against experimental data, rigorous validation steps, and the application of refined meshing techniques to capture detailed thermal behaviors.

Common outputs include temperature profiles, heat fluxes, thermal gradients, and predictions of thermal-induced stresses and deformations, which are crucial for assessing design viability and safety.