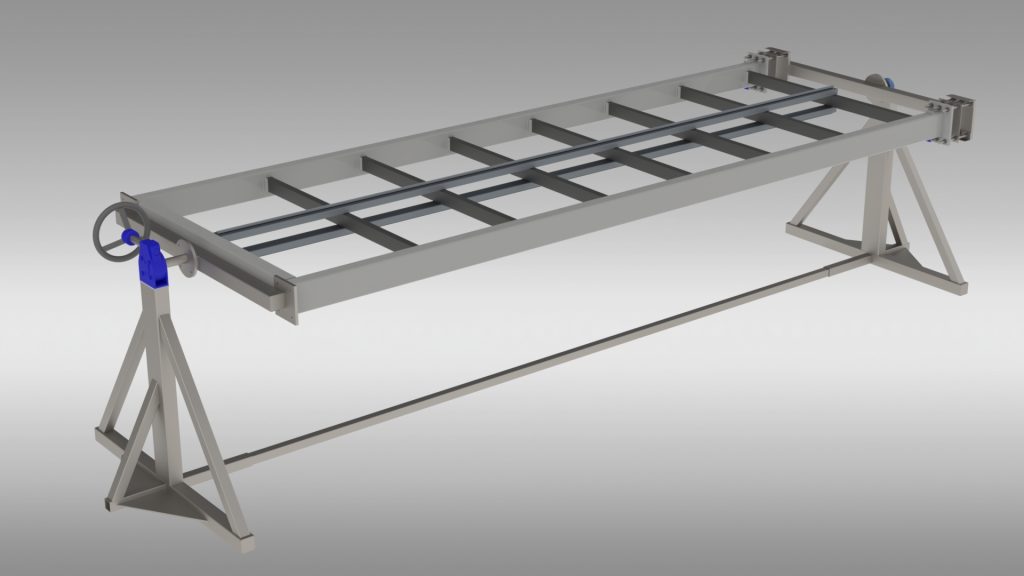

Frame fixture for Welding Ease in Pylon Signage Fabrication

- Home

- Business Case Studies

- Frame fixture for Welding Ease in Pylon Signage Fabrication

Client

An Australia-based metal fabrication company specializing in Pylon signage fabrication, structural steelworks, and custom heavy-duty frameworks for commercial and infrastructure projects.

Objective

To design and implement a robust frame fixture that simplifies the welding process during the fabrication of large pylon signage, improving both efficiency and safety on the shop floor.

Needs

Pylon signage structures are typically tall, heavy, and require precision during assembly and welding. Manual handling or unsupported setups can lead to:

- Misalignment during welding.

- Operator safety risks.

- Increased fabrication time.

- Inconsistent weld quality.

A specialized frame support structure was needed to:

- Secure the signage components.

- Allow controlled rotation and access to all weld joints.

- Streamline the assembly process for fabricators.

Challenges

- Structural Load: Supporting heavy signage steel components during welding without deflection.

- Accessibility: Providing 360° access for welders without repositioning the entire assembly.

- Stability vs. Mobility: The fixture needed to be stable enough to hold parts securely, yet adaptable for various signage dimensions.

- Rotation Mechanism: Incorporating a safe and controlled way to rotate the pylon during fabrication.

- Material Handling: Ensuring safety during loading/unloading and during rotation.

Solution

A custom-designed frame support system was engineered with the following features:

Feature | Description |

Heavy-duty SHS/RHS Frame | Built from 100×100 and 200×100 SHS/RHS mild steel for strength and rigidity. |

Rotating Shaft & Plates | Ø60 mm shaft supported by pedestal bearings enables safe rotation of the pylon for welding access. |

Reinforced Gusset Plates | 10 mm gussets improve stability and reduce frame flex under load. |

Base Plates & Mounts | Multiple plate thicknesses (10–16 mm) ensure firm anchoring during use. |

Precision Tolerance | Fabrication tolerances as low as 0.1 mm for key fits ensure precise alignment. |

Safety Features | Burr-free, capped ends to minimize injury risk; robust mechanical support to prevent tipping. |

Result

The implementation of the frame fixture resulted in significant fabrication benefits:

- 50% faster welding time due to easier part access.

- Improved weld quality and alignment accuracy.

- Reduced risk of workplace injuries and handling mishaps.

- Versatile setup allows use across multiple signage projects with varying sizes.

Client Feedback

“The frame system has completely transformed how we handle large signage fabrication. Our team feels safer, and we’ve cut down welding time dramatically. It’s a solid, reliable fixture that’s now part of our standard process.”

—Richard, Signage Systems