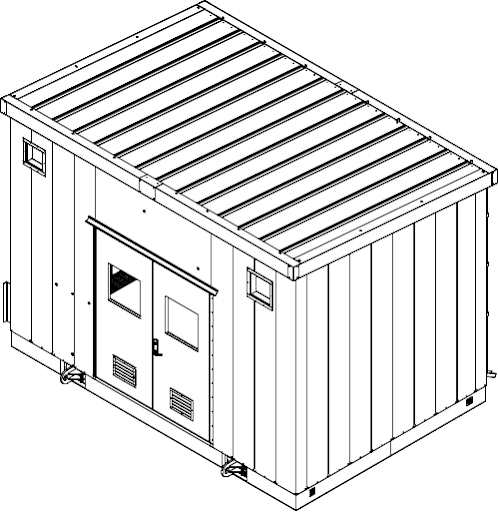

Metal Frame Modular Building Design for a New Zealand-Based Fabricator

- Home

- Business Case Studies

- Metal Frame Modular Building Design for a New Zealand-Based Fabricator

Client

A New Zealand-based metal fabrication company specializing in modular building systems for commercial and residential applications.

Objective

To develop precise 3D models and detailed fabrication drawings for a modular metal frame building. The design needed to incorporate structural integrity, ease of assembly, and be divided into transportable sub-assemblies.

Needs

- Accurate 3D Drawings: Comprehensive 3D models that detail every structural component of the metal frame, ensuring precision and ease of manufacturing.

- Structural Part and Welding Details: Detailed structural part specifications, including material type, dimensions, and tolerances, alongside welding guidelines for strong, durable joints.

- Precision in CNC Fabrication: The project required highly accurate DXF files for CNC machines, demanding precise alignment, tolerances, and consistent quality across multiple enclosure designs.

- Transportable Sub-Assemblies: Divide the modular frame into manageable sub- assemblies to facilitate easy transportation and efficient on-site assembly.

Challenges

- Structural Complexity: Ensuring structural integrity while designing modular sub- assemblies that could be easily transported and assembled on-site required intricate planning and modeling.

- Welding Precision: Specifying accurate welding details to ensure strength and stability, especially in joints subjected to high stress, was critical.

- Compliance with Local Standards: The design had to comply with New Zealand’s building and safety standards, which required close attention to structural specifications and safety guidelines.

- Efficient Sub-Assembly Design: Balancing ease of transport with structural robustness in each sub-assembly without compromising the overall design integrity was essential.

Solution

Zeta Cadd leveraged SolidWorks to meet the project’s complex requirements:

- 3D Modeling: Developed accurate 3D models detailing each structural part, creating a clear visual and functional representation of the modular frame.

- Structural and Welding Details: Provided detailed part specifications, material requirements, and welding instructions, ensuring robust and durable connections throughout the structure.

- Modular Sub-Assemblies: Divided the metal frame into transportable sub- assemblies, optimizing each one for stability during transport and easy on-site assembly.

- Fabrication Drawings: Created comprehensive drawings specifying dimensions, material gauges, and manufacturing details to facilitate quick and accurate production.

- DXF Generation: Produced DXF files ready for CNC cutting, enabling precise fabrication with minimal setup and alignment time.

Result

- Delivered comprehensive 3D models and detailed fabrication drawings that met all structural, welding, and modularization needs of the project.

- Improved the client’s production efficiency and assembly accuracy with well- organized, transportable sub-assemblies.

- Enabled faster installation on-site, reducing logistical complexity and enhancing project timelines.

Client Feedback

“Zeta Cadd’s team was instrumental in bringing this modular project to life. Their attention to detail in structural and welding specifications, coupled with the clear transportable sub- assemblies, made our fabrication and assembly process smooth and efficient. We look forward to future collaborations!”