Pressure Vessel Design Calculation & Technical G.A. Drawings

- Home

- Business Case Studies

- Pressure Vessel Design Calculation & Technical G.A. Drawings

Client

A Canadian-based company in the Chemical Process Industry, specializing in distillation plants, located in Port Colborne, Ontario.

Objective

The client required the complete engineering design of a vertical pressure vessel (distillation column reflux tank) for use in their chemical process facility.

Needs

The vessel had to comply with ASME Section VIII, Div. 1 and CSA B51 codes. It also needed to meet specific process conditions for handling both process fluid (EM) and internal heating/cooling coils.

Challenges

The client required the complete engineering design of a vertical pressure vessel (distillation column reflux tank) for use in their chemical process facility. This vessel had to comply with ASME Section VIII, Div. 1 and CSA B51 codes while meeting specific process conditions for handling both process fluid (EM) and internal heating/cooling coils. Key challenges included multi-nozzle configurations, internal/external coil connections, and strict mechanical and process safety standards.

Solution

Zetacadd Engineering Services provided an end-to-end engineering package covering both design calculations and technical fabrication drawings:

Design Calculations:

- Pressure Vessel Design per ASME VIII, Div. 1 & CSA B51

- Calculations for:

- Internal and external pressure conditions (F.V to 0.345 MPaG for vessel, 0.97 MPaG for coils)

- Torispherical head design (10% depth)

- Hydrostatic test pressures

- Nozzle reinforcement pad checks for various nozzles ranging from ½” to 8”

- Coil design for >3.2 m² surface area

- Vessel weight calculations (empty, working, and full water weight)

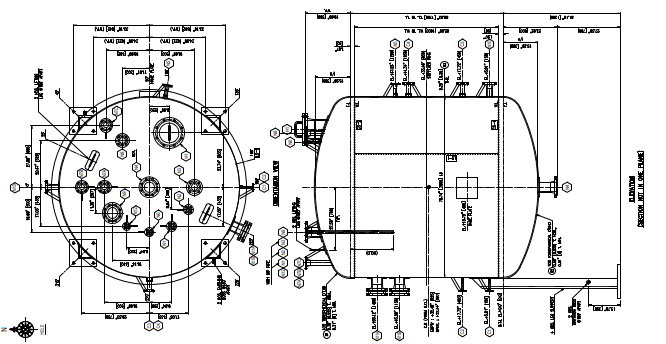

Technical Drawings:

- General Arrangement (G.A.) Drawings

- Full vessel dimensional details: 2000 mm ID × 1700 mm TL

- Detailed nozzle schedule (18 nozzles + 2 coil systems) with ASME #150 rating

- Hand hole and manhole arrangement

- Coil inlet/outlet positions

- Accessories: sight glasses, level gauge nozzles, lifting lugs, and brackets

- Skirt support layout and anchoring provisions

- Skeleton assembly drawings including platform, ladder, and nameplate positions

Materials & QA Requirements:

- All pressure parts specified in SS316L

- Coils in Duplex Stainless Steel

- Bolts/nuts to ASME A193 Gr. B8 / A194 Gr. 8

- Hydrostatic test and pneumatic test protocols included

- Surface treatment: pickling for inside and outside

Result

The client received a complete design package ready for fabrication approval and regulatory submission. This included:

- Comprehensive ASME-compliant design calculations

- Fully detailed, labeled fabrication drawings

- Optimized coil and nozzle layout for operational flexibility

- Improved process safety and reliability through rigorous design validation

The project was successfully delivered on schedule, contributing to the timely commissioning of the distillation unit for Project Eagle.