Spiral Staircase Product Development for The Iron Shop

- Home

- Business Case Studies

- Spiral Staircase Product Development for The Iron Shop

Client

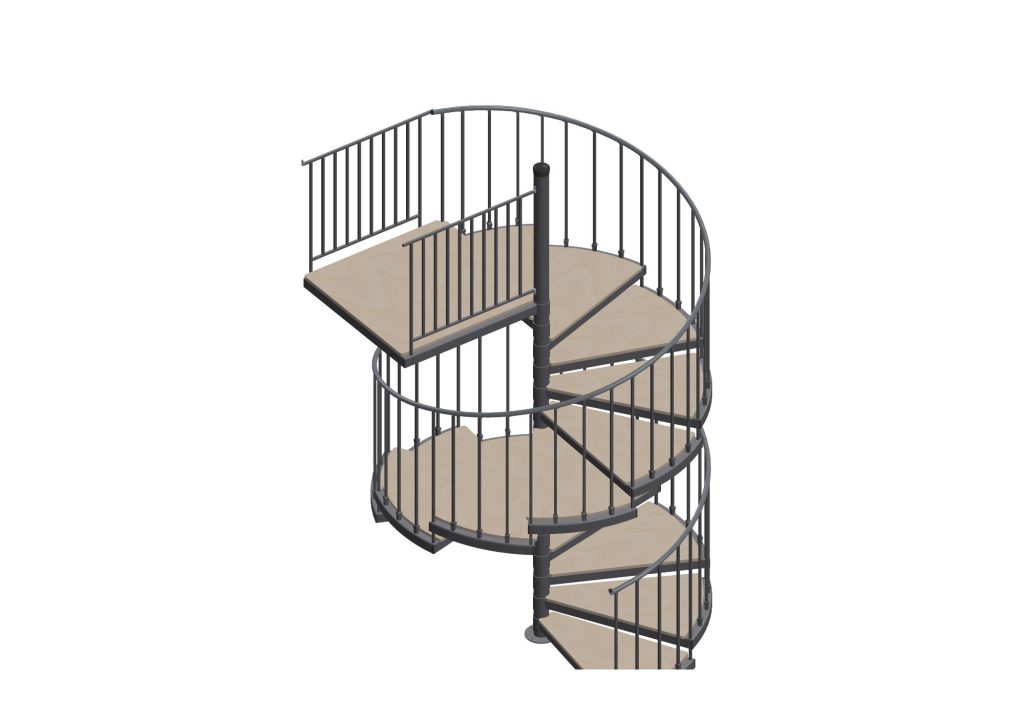

A renowned U.S.-based manufacturer of spiral staircase kits, approached Zetacadd Engineering Services to support the development of a new spiral stair product line. The goal was to create a fabrication-ready and installer-friendly product that could be produced at scale and easily assembled by end users.

Zetacadd partnered with client through every critical stage—from design engineering to customer documentation.

Objective

- Translate product vision into a fully engineered spiral stair kit

- Create a modular and scalable design for multiple stair diameters and material variants

- Ensure code compliance and user safety

- Develop a professional-grade installation manual for residential and commercial installers

Needs

- A fully engineered spiral stair kit that is modular, scalable for various diameters and materials, compliant with safety codes, and supported by a professional, user-friendly installation manual. The product needed to balance aesthetic appeal, structural integrity, manufacturing efficiency, and maintain dimensional accuracy across different materials.

Challenges

- Designing a staircase system that balances aesthetic appeal, structural integrity, and manufacturing efficiency

- Maintaining dimensional accuracy across different materials (metal, wood, vinyl)

- Communicating complex assembly steps to a non-technical audience

- Ensuring the design meets the California Building Code (CBC 2019) and L.A. Standard #111 guidelines

Solution

- Product Engineering & Design Refinement

- Zetacadd collaborated closely with the client’s design team to engineer every component of the stair system:

- Center pole sections with modular joinery for variable heights

- Tread assemblies designed for strength, simplicity, and visual appeal

- Spindle and handrail interfaces for structural stability and ergonomic flow

- Top landing and railing details optimized for ease of assembly

- Through detailed 3D modeling and feasibility analysis, we ensured the design was cost-effective for production and simple for users to install.

- Fabrication-Ready CAD Drawings

- We produced a comprehensive technical drawing set, which included:

- Exploded views and assembly sequencing

- Precise hole locations, tolerances, and fastener specs

- Fixing techniques and part identification

- Clear fabrication standards for manufacturing partners

- The result: faster production turnaround and reduced dependency on rework.

- Custom Installation Manual

- Understanding that a well-documented product builds customer trust, Zetacadd designed and authored a user-friendly installation manual, complete with:

- Sequential diagrams for each assembly stage

- Tool and hardware lists tailored to end users

- Detailed steps for metal, wood, and composite finishes

- Guidance for optional add-ons like safety gates, inner handrails, and balcony railings

- This manual helped the client to provide a premium DIY experience with reduced support calls and better user satisfaction.

- Code & Safety Compliance

- We embedded regional compliance requirements directly into the design phase, referencing:

- L.A. Standard Plan #111

- California Building Code (2019 CBC)

- IRC stair safety standards for residential use

Every aspect of the stair—from riser height to spindle spacing—was validated for structural and regulatory integrity.

Result

• Reduced product launch time by streamlining design-to-documentation workflow

• Lowered manufacturing costs through optimized fabrication drawings

• Improved user satisfaction and assembly success with an intuitive manual

• Created a reusable platform for multiple stair variants and materials

Client Feedback

“Zetacadd played a key role in helping us bring a new stair product to life. Their engineering insight, attention to detail, and documentation quality made this launch one of the smoothest we’ve had.”