Production Documentation and Detailing

- Home

- CNC Programming Services

- Production Documentation and Detailing

Shop-Floor Documentation that Eliminates Guesswork

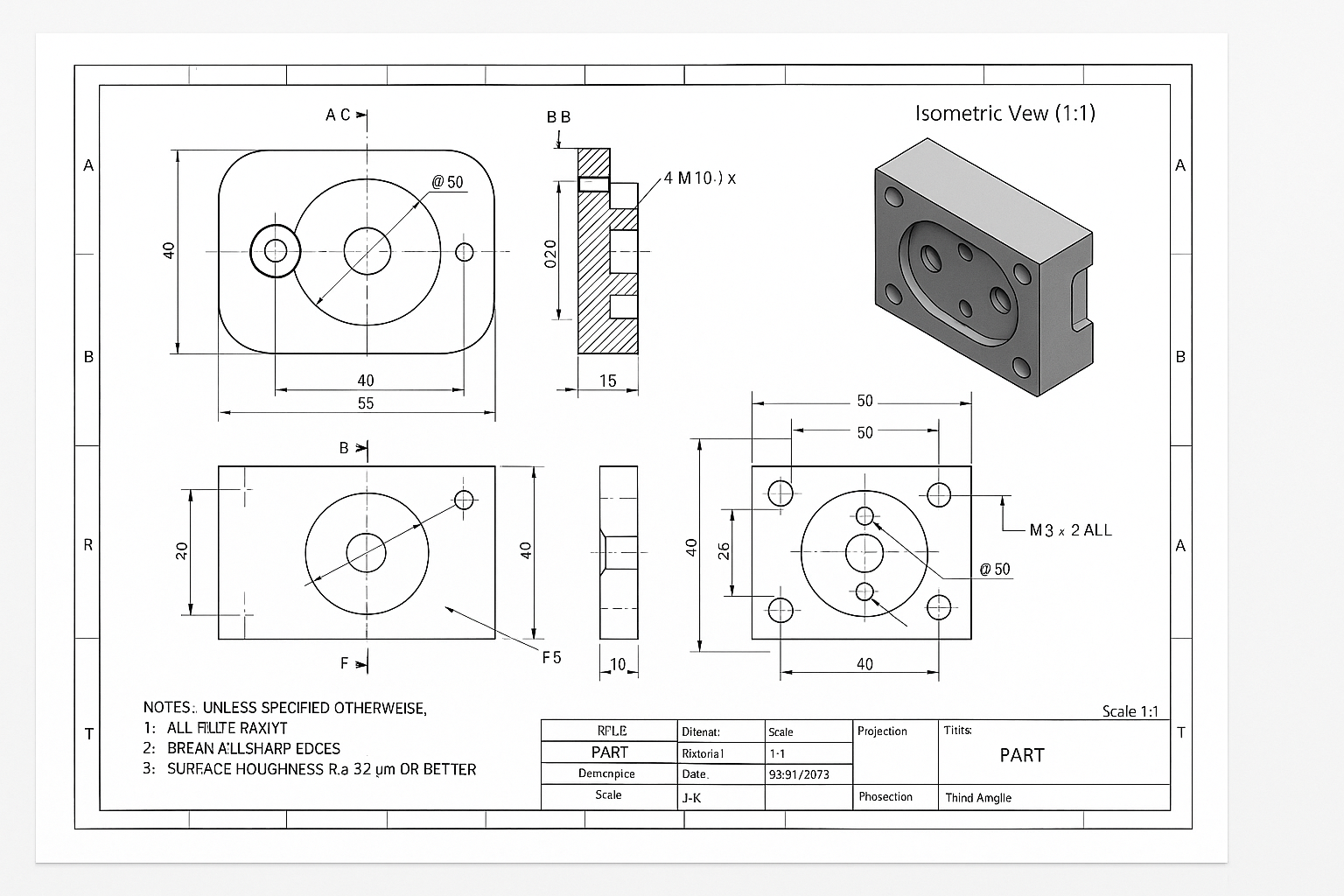

Even the best CNC program falls short without clear, production-friendly documentation. Our Production Documentation and Detailing service bridges the gap between design and fabrication, offering your shop-floor teams the clarity they need to assemble, identify, and finish parts with confidence. We prepare visual guides, labeled part sheets, tolerance notes, and material callouts so your operators don’t have to interpret technical drawings on the fly.

Tools We Use

What We Provide

Assembly Guides and Exploded Views

Clear, step-by-step illustrations showing how each component fits together—ideal for modular furniture, fixtures, or multi-part assemblies.

Part Identification and Labeling Maps

Each part is labeled with an ID, orientation arrow, and reference to its sheet location, making sorting and edge-banding more efficient.

Material and Hardware Callouts

Every file includes notes on panel types, thicknesses, edge finishes, hardware zones, and machining tolerances, ready to hand over to your procurement and cutting teams.

Cut Lists and BOMs

Detailed cut lists generated directly from the nesting layout or 3D model, with part dimensions, quantities, and material usage summaries.

Tolerance and Clearance Annotations

Critical fits and gaps are flagged in the documentation so that your machinists and fitters know exactly where precision matters and where some play is acceptable.

Printable Operator Packs

All deliverables are bundled into easy-to-read PDF sheets or digital packages that can be viewed at the workstation or printed and hung near the machine.

Our industries

-

Machine Manufacturing

-

Automobile Industry

-

Oil & Gas Industry

-

Heavy Fabrication

-

Sheet Metal Manufacturing

-

Millwork Joinery

-

Furniture Manufacturing

CAD conversion Process

The CAD conversion process at ZetaCADD involves a meticulous approach from physical or outdated designs to accurate and editable digital CAD files.

Consultation

Our technicians consult with clients and try collecting as much information about the project.

Quotation

After the scope of the project is understood, our experts evaluate and offer a price quote.

Feedback & Reviews

To prevent any last-minute changes, Polosoft prefers to get client input at every stage.

Delivery

Final drafts are checked by our professional team of quality analysts.

Turn design files into clear, buildable instructions

Empower your team with the information they need; no confusion, no wasted time.

Introduce Our Projects

Testimonials

Courtney Henry / Customers in U.S.A

Marry Tonheim / Customers in UK

Anna Richmond / Customers in SA

Read Most

Frequent Questions

Yes. Wherever applicable, we create exploded diagrams showing part relationships and fastener positions for smooth assembly.

Absolutely. We generate cut lists and material summaries for every batch or project layout.

Yes. Our drawings can mark edge banding sides, laminate surfaces, and grain orientation as needed.

Yes. We can format documentation in your preferred unit system based on your production standards.

Typically as a PDF bundle including layout sheets, part IDs, material specs, and optional DWGs. We can also export data into Excel or CSV for your internal systems.

By default, we deliver in English—but multilingual annotations or versions can be provided on request.